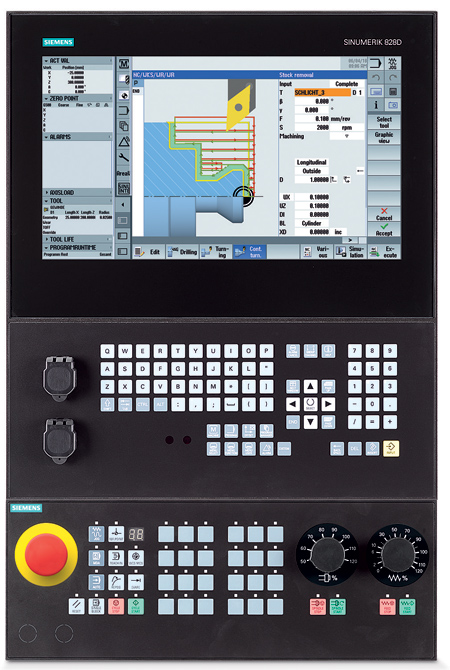

Sinumerik 828D is a panel-based control for mid-range CNC machines. Featuring a 10.4" color or 15.6" multi-touch display, the 828D is suited for milling, turning and grinding applications.

Siemens presented its mid-range CNC, the Sinumerik 828D, with version 4.8 of the operating system at IMTS 2018. With the release of version 4.8, Siemens offers an array of new hardware and software solutions for its integrated Sinumerik portfolio. The offering comprises integrated industrial software and automation technology designed to enable machine tool manufacturers to leverage the full productivity potential of the digital factory in a mid-range control.

Sinumerik 828D is a compact, panel-based CNC, offered in vertical and horizontal models for highly flexible machine design integration, while the resident Siemens technologies of Advanced Surface and Top Surface are designed to ensure optimum surface finishes with 80-bit nano floating point accuracy. Also, standard on the 828D are the Siemens Shop-Mill and Shop-Turn graphical programming with interactive input help through animated elements. Up to 10 axes of motion with two auxiliary axes are possible. Color displays, in sizes 10.4" or 15.4", and the Simatic S7 PLC are also standard. "With three steps in the new software version, depending upon the motion control needed, Siemens is bringing the 828D standard models to a competitive price point for the builders of CNC milling, turning and grinding machines," said a company spokesperson.

With software release 4.8, Siemens is making a range of new functions available to improve the speed, precision and safety of intermediate milling, turning and grinding machine tools, with simplified ISO code programming. Features of version 4.8 include a facility for compensating unwanted axis nodding movements and protection against machine, tool and workpiece collisions. Nodding compensation (NoCo) is used to compensate for dynamic position deviations in one or more linear machine axes caused by acceleration processes. These position deviations are caused by what is known as mechanical compliance within the machine. NoCo compensates for the dominant position deviation by initiating a corrective movement in the relevant machine axis, enabling improved machining quality simultaneously with higher jerk and acceleration values. Nodding compensation can be used in conjunction with any technology, such as milling, multitasking, tapping, laser machining or water jet machining. NoCo is available in two variants: Eco and Advanced. The Eco variant is designed for dominant acceleration effects in which the compensation axis is combined with one influencing variable. Where there are several influencing variables which require several compensation axes, the Advanced variant is the option of choice.

The Sinumerik software release 4.8 also features a collision protection: Collision Avoidance Eco and Collision Avoidance Advanced. The Eco version enables machine protection by preventing collisions of the machine body with its own components within the work area.

To achieve this effect in real-time, the assemblies which need protection are calculated as simple geometric bodies. This collision monitoring system is available in all three operating modes: JOG, MDA and Automatic. The protected areas can be engineered and visualized as a 3-D image at the control interface. The Advanced variant includes full machine, tool and workpiece protection. The software provided by the Sinumerik product partner ModuleWorks runs via an interface integrated on an external PC and works together with the Sinumerik CNC in real-time to ensure that the machine, tool and workpiece can be continuously monitored and are protected during the stock removal process. The workpiece and tool data required is made available to the system during set-up. Collision Avoidance provides safety during operation.

For more information contact:

John Meyer

Siemens Industry, Inc.

390 Kent Avenue

Elk Grove Village, IL 60007

847-640-1595

cnc.marketing.us@siemens.com

www.usa.siemens.com/cnc