The Tower Module features 10 shelves and is placed on top of the Slave Module. This tower can store various material types and features a symmetrical design for placement flexibility.

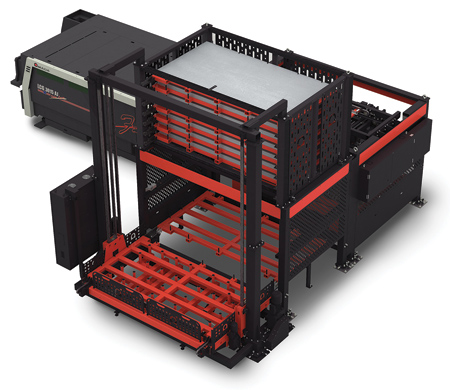

Amada America offers a modular system cycle loader, the AMS 3015 CL. Amada engineered the modules to integrate together seamlessly in various configurations, allowing the customer the ability to quickly upgrade this laser automation solution. As the system is expanded, existing modules stay in place or are reconfigured to meet specific layout requirements.

Some of the major modules that allow the AMS CL to easily increase its automation capabilities and flexibility include a Master Module, Slave Module and Tower Module.

The base module required for automating a single laser is a Master Module that is placed over the laser's shuttle table. This module performs sheet loading and unloading operations.

The Slave Module, where raw material is loaded and finished sheets unloaded, can be placed in the front or rear side of the Master Module. Its symmetrical design helps accommodate production flow.

The Tower Module features 10 shelves and is placed on top of the slave module. This tower can store various material types and also features a symmetrical design for placement flexibility. By adding an additional tower, customers can more than double material storing capacity (with 16 additional shelves) and enable high-volume, unattended production.

The 3015 designation represents the 3.0 m x 1.5 m size of this system, allowing it to easily accommodate 5' x 10' sheets of material.

All AMS CL modules feature a symmetrical design that allows their placement to be either on the front or rear side of a laser cutting system. This type of flexibility is key, especially if a shop's floor layout changes in the future.

Compatible laser machine models include Amada's LCG AJ, ENSIS AJ, FLCAJ, FOL AJ, LCG, FOM2 NT and LC F1 NT.

"Through continuous development, the AMS CL will have the potential to be part of a complete blank-to-bend solution," said a company spokesperson. "The fully integrated solution will feature a Part Sorting Robot (PSR) that unloads parts from the blanking area to a robotic bending system with automatic tool changer."

For more information contact:

Amada America, Inc.

7025 Firestone Blvd.

Buena Park, CA 90621

714-739-2111

www.amada.com