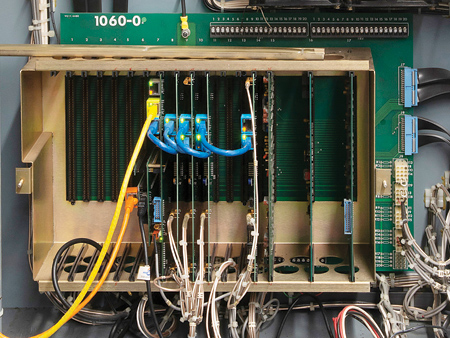

A closeup of the 527F installed in a Fadal. Note the orange Ethernet cable, a must-have for shops that want to make their machines network capable.

Fadal CNC 88 Calmotion full color screen

Calmotion LLC recently released its new 527F CNC, which company president Walter Calmette describes as an easy to install, high-performance control replacement for virtually any model of Fadal CNC machine.

"The 527F and the Fadal legacy control can quite literally be swapped back and forth within minutes," said Calmette. "Although the newer control does require a VGA monitor, something the company offers, the replacement control uses the machine's existing wiring and cabling and does not require any additional modification."

"This is more than a way to get a tired or broken Fadal up and running quickly. The new control offers advanced ramping functions and block processing times that increase machining productivity without compromising part integrity. Most customers using the new control are able to double their feedrates, with some reporting even greater improvements-a mold maker in Lawrenceville, GA, for example, said he was able to increase feedrates on a 3/16-inch end mill from 50 IPM to 180 IPM, with room to spare," said a company spokesperson.

"If I had taken the time to reprogram the job for a larger cutter, I am pretty sure I could have hit 250 IPM," said Baitjunkys Owner Leonard Smith. "As it was, I reduced my cycle time from 4-1/2 hours to just over two, without changing anything but the feedrate."

For those concerned about the time needed to learn a new machine control or modify hundreds or even thousands of existing programs, the 527F's user interface and commands have a familiar look and feel; no operator training is required. Similarly, existing legacy programs are compatible and require no modifications.

"The new control is also easier to use, with a number of set-up features to aid even experienced operators in getting the machine running quickly and efficiently. In particular, the 527F features a powerful and flexible memory system for CNC file management, a shortcoming of the Fadal control," said the spokesperson. An Ethernet connection and USB memory interface are standard, as is 16 GB of user program space, providing a variety of convenient ways for operators to load and save files. Wireless capability is also available using commercially available network routers, further streamlining the NC file management process.

As mentioned earlier, it is also quite fast. Based on an embedded platform and multi-processor core, the 527F utilizes a parallel processing control architecture to ensure the fastest control loop updates possible without the burden of an operating system. And since each axis is controlled with its own digital signal processor, the 527F can handle a variety of 4- and 5-axis applications without any loss in block processing capability.

"We are basically picking up where Fadal left off," said Calmotion Software Engineer Glenn de Caussin. "The CPU has probably 20 to 30 times more processing power than the legacy controls. We have far better ramp control, something that was pretty much nonexistent before. For anyone with a Fadal that is still in good shape-which most of them are-it is an inexpensive option to significantly increase productivity without all the hassle that is typical of retrofit controls."

Calmette agrees: "We recently redesigned the hardware so that everything would plug into the existing motherboard. There is no need for a technician or even any sort of electronics experience-it is about as close to plug & play as you can get with a piece of industrial machinery. Along with its advanced motion control capabilities and usability, that is what sets us apart."

For more information contact:

Calmotion LLC

7536 San Fernando Road

Sun Valley, CA 91352

818-357-5826

www.calmotion.com