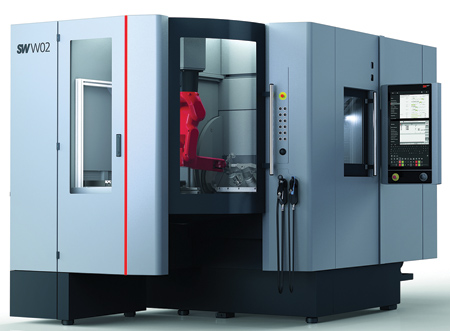

SW has released two new manufacturing cells designed for plug & play-capable manufacturing cells to shorten customer commissioning time. The systems consist of the two-spindle BA 222 or BA W02-22 together with a newly developed loading module with integrated 6-axis robot and vertical pallet storage for blanks and finished parts.

For especially cramped conditions, the manufacturing cell is available in a version with the loading module specially designed as a corner solution with transverse material flow. This variant features an arc-shaped robot loading door and allows for nearly unrestricted access for all set-up tasks at the loading station.

"Most solutions available on the market do not allow for any direct access for set-up tasks on the machine. These tasks have to be carried out awkwardly through the open protective fence," explained Wolfgang Armleder, Director of Development at SW. "By contrast, our manufacturing cell allows for nearly unrestricted access for all set-up tasks at the loading station."

Manufacturing cells with a supply of workpieces for one shift are used in many applications for machining complex workpieces-from the automotive industry to medicine and precision engineering. Many automation solutions in the past have been two-part systems that required a good deal of time and effort to integrate into the process chain.

Schwäbische Werkzeugmaschinen GmbH (SW) has released two new manufacturing cells designed for plug & play-capable manufacturing cells to shorten customer commissioning time. The systems consist of a BA 222 or BA W02-22 machine tool together with a newly developed loading module with integrated 6-axis robot and vertical pallet storage for blanks and finished parts.

The module enables loading and unloading of the machining center in parallel to machining time and is completely flanged onto the basic machine in the SW plant. The machine, robot and workpiece storage are designed as a crane hook solution to meet specific customer needs. Overhead robot mounting allows more freedom of motion. The workpiece storage is set off to the side, thus also allowing for manual loading of tools into the machine while requiring very little space. A manufacturing cell with loading module is also planned for the machining center model BA 322.

Independent manufacturing cells also help ensure both a high level of availability and easily scaled manufacturing capacity while lowering production costs. "They are especially well suited if a company is relying more on multi-shift operation, which means that one employee is responsible for several machines," said Wolfgang Armleder, Director of Development at SW. "Independent cells can also be used if quality and process data have to be reliably tracked. Loading modules form an ideal basis for this because their deposit pattern is always nearly identical and outward transfer of SPC measured parts can be planned."

SW developed a loading module for the BA 222 and BA W02-22 machining centers with integrated robot and workpiece storage that eliminates these problems. The module is flanged onto the basic machine and completely set up before it leaves SW. "In this context, flanged on means that the components are mechanically connected, the coolant return and swarf return to the swarf conveyor are set up and the electrical installation is performed," said Armleder. The two components-loading module and machine tool-combine to form an independent manufacturing cell together with a supply of workpieces for one shift. The cell is delivered as a plug & play-capable complete system, resulting in short commissioning times for customers.

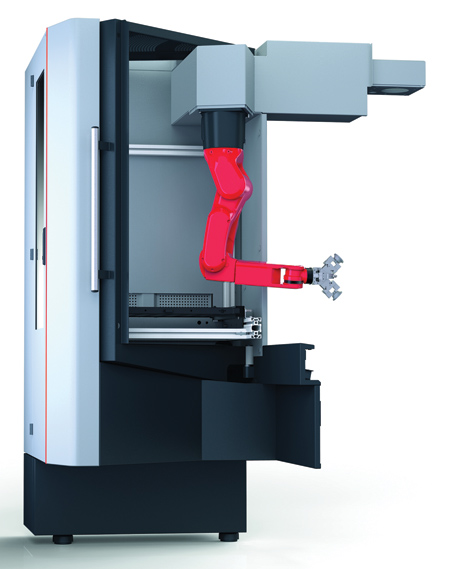

Overhead Robot Mounting

The loading module is designed so that the machine, robot and workpiece storage are arranged as a crane hook solution to meet specific customer needs. "SW machine tools feature a patented monoblock construction that is critical for the stability and accuracy of the machining center. This design shape makes overhead mounting of the robot very advantageous," said Armleder. Since the robot can also be flexibly configured for specific projects, there is more freedom of movement and space for other technologies. For example, other processes can be integrated, including reclamping, labeling or scanning. The loading module is fitted with standard aluminum support profiles for this purpose for fast and universal use holding these additional devices.

The powerful 7 kg robot is suitable for workpiece dimensions of up to 100 x 100 x 50 mm with a weight of up to 1.0 kg and makes it possible to use multiple grippers and move the pallets. In addition to loading and unloading in parallel to machining time with an integrated 6-axis robot, the system also makes it possible to perform this step manually. This is helpful, for example, with small batch sizes. It is also possible to exchange the workpiece supply in parallel to system production time. The design of the loading module, with the workpiece storage set off slightly to the side, also makes it possible to use the manufacturing cell under difficult conditions. "This design features a special arc-shaped robot loading door and allows for nearly unrestricted access for all set-up tasks at the loading station," said Armleder. "We created a special solution for this so that swarf and coolant can be reliably diverted from the entire robot area into the swarf conveyor."

High Storage Capacity

The vertical pallet storage for blanks and finished parts, integrated into the module, can be fitted with a maximum of 24 pallets measuring 600 x 400 mm. Since a pallet has space for 48 passenger car compactor impellers, for example, the storage capacity is 1,152 blanks and/or finished parts. The system runtime, with a cycle time of 1 minute for every two workpieces, is accordingly 9.6 hours, which would be equivalent to a belt conveyor 64 m long. In contrast to many previous solutions, pallet transport is not based on chain systems, which are susceptible to failure, but instead on an elevator car with wear-free ball screw drive. This system allows for loading and unloading of pallets at an ergonomically optimum and consistent height. The elevator car is also designed as a freely programmable positioning axis.

For more information contact:

SW North America

30160 Lyon Industrial Ct.

New Hudson, MI 48165

734-736-4072

contact.na@sw-machines.com

https://www.sw-machines.de/en.html