Fully Automated 3-D Fiber Laser Tube Cutting System

December 1, 2016

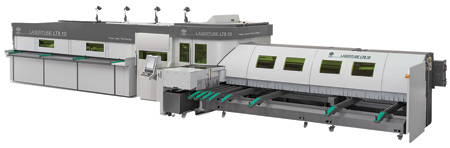

BLM GROUP Model LT8.10 tube processing system

BLM GROUP USA has announced the introduction of the Model LT8.10 fiber laser tube cutting system.

The LT8.10 is a 3-D, 3 kW fiber laser tube cutting machine that provides flexibility and user-friendliness for precise laser cutting on a variety of materials for tube diameters up to 9.5". The system is also suitable for cutting highly reflective materials such as brass, copper and aluminum and can process round, square, rectangle, flat oval and D-shaped tubes, as well as open profiles such as C and U shaped channel bar.

The unit is equipped with the "Tube Cutter" 3-D cutting head developed exclusively by BLM GROUP, which is compact and lightweight, designed for a variety of tube cutting applications including tilt cutting of thick-walled steel. It is capable of making tilt cuts with accuracy and quality in tubes and in open profiles and contours. The LT8.10 is available in multiple load and unload configurations including an automatic bundle loader, automatic step loader and/or a manual single bar loader. Complex operations such as nesting multiple part numbers on the same bar and changing to different profiles, are managed automatically.

The LT8.10 incorporates a variety of functions including Active Marking for part marking and tracking; Active Piercing to increase piercing speed for productivity; Active Scan to deal with material variation; Active Speed to sustain quality across all cutting conditions; and Active Focus, a technology that adjusts beam focal position. Each function is instrumental in the productivity and ease-of-use of the machine.

The LT8.10 takes advantage of the BLM GROUP's proprietary suite of tube processing software entitled BLMelements. BLMelements is a set of tools for designing parts, estimating production times, creating part programs, planning production and if need be, integrating with other BLM GROUP machines. The software allows remote machine monitoring, collecting operating statistics and receives real-time notifications of events that may require attention.

For more information contact:

BLM Group USA

29380 Beck Road

Wixom, MI 48393

248-560-0080

sales@blmgroupusa.com

www.blmgroup.com

< back