Marposs' integrated Machine Monitoring Solutions enable data-driven manufacturing for informed decision-making.

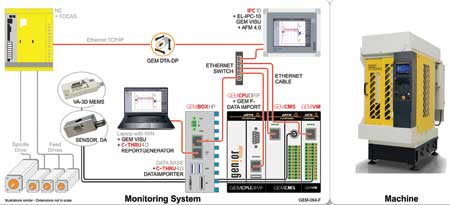

Marposs recently demonstrated its smart manufacturing solutions, including Artis Machine Monitoring Solutions (MMS), Mida probes and tool setters and software platforms including the C-THRU4.0 data management system. Marposs featured a FANUC Robodrill equipped with a drill, tap and milling cutter with Artis sensors that collect and stream real-time data. This provides visibility into the current status of production equipment, tools and cutting processes. This information is collected via spindle and linear axis power monitoring, spindle bearing vibration signals, machine crash signals for mitigating machine damages and energy monitoring data signals, including OEE basic figures to optimize the manufacturing process. This information helps to minimize damage caused by collisions and crashes, and helps predict maintenance needs, reducing energy usage and production costs, as well as improving throughput.

The display system at IMTS featured Marposs' Energy Monitoring System that leads to energy cost reduction, CO2 footprint reduction and electrical CBM. It is equipped with multisensors and sensorless technologies that provide the following:

- Simultaneous analysis of main spindle and load power

- Vibration signature analysis

- Machine crash protection

- Electrical Condition Based Monitoring (CBM) for energy monitoring.

Additionally, the system provides Overall Equipment Efficiency (OEE) process and tool monitoring data for visibility into tool comparison, cause of inefficiencies, production count, tool cost/part, part report, traceability and more.

Data was also collected from the Marposs Visual Tool Setter (VTS), which provides camera tool inspection for tool setting and advanced measurements and the Marposs Ultra Probing System, a radio spindle probe for part inspection and positioning.

Data streaming from the smart manufacturing system can be visualized in a variety of ways, including:

- Data capture on a dedicated Industrial Control Panel

- Data streaming through the MAINDO Digital Platform that integrates Marposs monitoring, measuring, testing, as well as other manufacturer's device/solutions throughout the entire production process, combining quality and process into a holistic production monitoring view.

For more information contact:

Marposs Corporation

3300 Cross Creek Parkway

Auburn Hills, MI 48326

248-370-0404

marposs@us.marposs.com

www.marposs.com