Machine-Optimized ESPRIT CAM Solutions for Willemin-Macodel

July 1, 2021

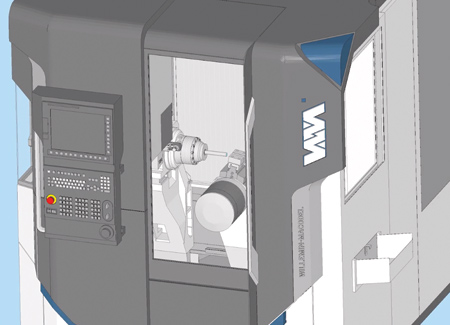

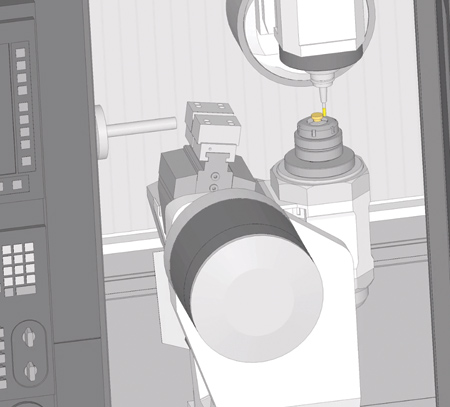

ESPRIT digital twin of Willemin-Macodel 508MT2

ESPRIT's highly optimized support for Willemin-Macodel

Willemin-Macodel is a supplier of made-to-measure machining solutions for complex, high precision workpieces in industries like watchmaking, jewelry, medical, aviation and more.

"Due to the innovative configuration and complexity of certain mill-turn machines (508MT, 508MT2 X400, 408MT), programming and simulating using conventional computer-aided manufacturing (CAM) software can be a challenge. Without the right software to drive those powerful machines, it is difficult to fully utilize their capabilities and realize their complete benefits," said a spokesperson.

By working directly with Willemin-Macodel and a number of key clients, ESPRIT CAM engineers developed highly optimized support for Willemin-Macodel within its CAM software to improve the user experience and programming efficiency for the MT series, including output of machine-optimized, edit-free G-code.

Some of ESPRIT's key capabilities for these machines include:

- Create and sort operations in the required work coordinates

- Optimize simulation to match the output NC code and actual machine behavior

- Display various operation information to make programming in ESPRIT easier

- Provide a simple interface to set global machine settings

- Offer an easy way to mount vise jaws on the turret

- Offer a quick solution to mount chuck and collet on the main and sub spindles

- Allow programming of tailstock engage and disengage cycles

- Enable programming of vise steady rest engage and disengage cycles

- Let the user flag a milling operation as a cut-off operation.

ESPRIT CAM engineers also worked closely with Willemin machine specialists to create a turn-key digital machine package consisting of post-processors and virtual machines for the MT series. This eliminates the time spent on editing the G-code and streamlines the machine set-up and first article run-off for the end users.

For more information contact:

ESPRIT CAM

1150 Avenida Acaso

Camarillo, CA 93012

805-388-6000

esprit@dptechnology.com

www.espritworld.com

Willemin-Macodel Inc.

5 Westchester Plaza

Elmsford, NY 10523

914-345-3504

info@wmusa.us

www.willemin-macodel.com

< back