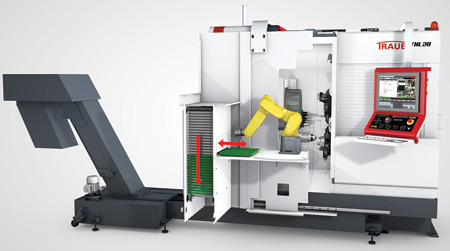

TRAUB TNL20-Productive sliding and fixed headstock turning of medium and high complexity workpieces from bar stock or with an integrated robot cell.

INDEX C200-Subsequent processes such as cleaning, measuring, deburring, etc. can be integrated in the robot cell.

INDEX G200-Robot cell is located on a platform equipped with linear guides and is fixed in front of the machine's work area during production.

INDEX G400-Modular robot solution for large machines.

INDEX offers productive robot automation solutions for small- and medium-sized turning and turn-mill centers, and recently released an easy-to-integrate automation system for customers with larger turning centers. Due to its modular design, the robot can be used not only for loading and unloading large, heavy workpieces, but also for a range of downstream tasks.

"In response to strong demand for automation solutions across its entire machine range, INDEX offers solutions that cover everything from simple workpiece removal devices integrated in the machines to sophisticated external robot solutions," said a company spokesperson.

Fully-Integrated Automation for Compact Machines

The compact TRAUB TNL20 sliding/fixed headstock automatic lathe can be configured with an iXcenter that is fully integrated with the machine. It consists of a jointed-arm robot and a vertical pallet storage unit that holds up to 14 pallets (300 mm x 400 mm). With this automation solution arranged at the front, the robot can load and unload chucked parts. It is also capable of sorting components after bar machining.

The iXcenter is already prepared for the integration of additional process steps, such as 3D measuring and deburring. For simple and ergonomic machine set-up, the user can push the small robot cell completely to the side after releasing a lock, allowing unrestricted access to the machine.

Automation Cell for Medium-Size Machines

INDEX offers a slightly modified version of its iXcenter robot cell for medium-size machines, such as the INDEX C100/C200 production turning machines, the INDEX G200 turn-mill center and now also the TNA and B series universal turning machines.

Instead of being directly attached to the machine, the robot cell is located on a platform equipped with linear guides and is fixed in front of the machine's work area during production. The 6-axis robot offers up to 12 kg load capacity and accesses the machine's work area via the machine door, which opens automatically behind the robot cell.

This version of iXcenter features a space-saving vertical storage system with up to 22 stacked pallets (600 x 400 mm). Pallets with blanks are loaded in the top storage area by the machine operator, while pallets with finished parts are removed from the bottom of the pallet storage unit. This can be done at any time without interrupting production. Downstream processes, such as cleaning, measuring and deburring, can also be integrated in the robot cell.

Modular Robot Solution for Large Machines

The newest iXcenter automation solution is designed for the new, large G-series turn-mill centers and is currently being presented on the INDEX G400. "Automation plays an important part in machines of this size (turning length up to 1,600 mm), since the weight of the parts typically causes the operator to require support during loading and unloading, such as using a crane. Additionally, manual chucking of these large parts takes a long time. Automated handling pays off relatively quickly in such cases," said the spokesperson.

The INDEX development team selected a modular design for the large iXcenter. The automation solution is comprised of a largely autonomous standard robot cell positioned in front of the machine. It is a base unit on which a jointed-arm robot is installed with a load capacity of 165 kg as standard (optionally up to 270 kg). Different modules can be docked to this cell from two sides, including pallet/rack systems, measuring/testing stations, equipment for deburring, cleaning or laser marking and more. This means that the robot is not only responsible for loading and unloading the parts via the machine door, but can also deal with downstream processes during what are often long machining times.

Flexibility with Standard Modules and Special Solutions

"As far as the robot's modules and operations are concerned, INDEX already covers a large spectrum with standard solutions, meaning that many customer requirements can be met quickly," said the spokesperson. These include, for example, the robot's gripper changer for automated and alternating handling of shaft and flange parts, which the robot loads into the machine from a pallet station. For this purpose, the robot automatically changes the corresponding grippers from the changing station.

INDEX is continually developing solutions to expand the spectrum of the large iXcenter solution. For example, since the robot can access both the main and counter spindles, solutions can be implemented for changing the clamping jaws in the machine. For the G420 turn-mill center, there are plans to enable the changing of special tools in future, since the tool magazine and milling spindle are also within the robot's field of action.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

us.index-traub.com

SOUTHWEST

NM

AME, Inc.

5770 Clarkson

Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

AR, LA

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

TX

Prosper Machine Tools, LLC

7415 Whitehall Street

Suite 123

Richland Hills, TX 76118

682-626-5537

www.prospermt.com

SOUTHEAST

AL, FL (Panhandle), MS, TN

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

NORTHEAST

CT, ME, MA, NH, W. PA, RI, VT

INIRAM Precision Machine Tool Inc.

333 North Main Street

Middleton, MA 01949

978-854-3037

www.iniram.com

DE, MD, NJ, S. NY, E. PA

Single Source Technologies, Inc.

2192 Winterberry Court

Warrington, PA 18976

610-430-3670

www.singlesourcetech.com

MIDWEST

S. IL, KS, MO

Dynamic Machine Tool, Ltd.

84 Hubble Drive

Suite 200

St. Charles, MO 63304

636-447-2900

www.dynamicmachinetool.com

N. IL

Integrated Machinery Systems

101 North Prospect Avenue

Itasca, IL 60143

630-250-8305

www.imscnc.com

MI

Methods & Equipment Associates

31731 Glendale Avenue

Livonia, MI 48150

734-293-0660

www.methods-equipment.com

MI (Upper Peninsula), E. WI

Premier Machine Tool Midwest

PO Box 102

Hartland, WI 53029

414-254-5150

www.pmtmidwest.com

IN, KY, OH

Technical Equipment

10165 International Blvd.

Cincinnati, OH 45246

800-852-0582

www.techequip.com

WEST

CO, WY

AME, Inc.

5770 Clarkson, Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

AZ

CNC PROS

1502 N 17th Ave.

Phoenix, AZ 85007

602-332-5815

www.cnc-pros.com

N. CA, NV (Reno & Carson City)

CNC Solutions

1011 Pecten Court

Suite A

Milpitas, CA 95035

408-586-8236

www.cncsolutions.biz

OR, WA

Ellis Machinery & Equipment, Inc.

6225 20th Street East

Fife, WA 98424

253-926-6868

www.ellismachinery.com

S. CA, NV (Clark County)

Protek CNC

25 W Easy Street

Suite 306

Simi Valley, CA 93065

805-579-9995

www.protekcnc.com