GibbsCAM Now Includes VoluMill

February 1, 2015

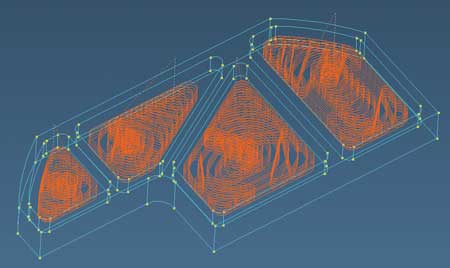

"Integrated with GibbsCAM, VoluMill provides high-speed material removal without the starts and stops of traditional parallel-offset roughing patterns, thereby maximizing removal rates while minimizing cutting tool wear," said a company spokesperson.

Gibbs and Associates has begun including a no-cost license of VoluMill Wireframe for GibbsCAM with each new license of GibbsCAM Production Milling. Until now, the high-speed toolpath engine was a fee-based option for GibbsCAM Production Milling, the primary milling package upon which a series of multi-axis GibbsCAM machining options integrate. Production Milling, which provides wireframe geometric modeling and toolpath generation for 2-, 2.5- and 3-axis machining, with 4th axis positioning, will now have VoluMill integrated within its interface. VoluMill Wireframe for GibbsCAM is a high-speed machining process developed to achieve high material removal rates while extending tool life through smooth transitions and constant tool loading. According to the company, customers have reported cycle time reductions as high as 70% and tool life extension of five times.

"Traditional roughing toolpaths are typically generated as parallel offsets with sharp corners and transitions, requiring stops, starts and variable speeds to optimize motion and protect cutting tools from excessive wear and breakage," said a company spokesperson. "In contrast, VoluMill generates toolpaths optimized for volumetric material removal by using continuous tangential motion, specialized contour ramping, adaptive feedrates and chip thickness control, achieving the highest feeds and speeds possible. By leveling tool load, maintaining constant machine-tool motion and using high-speed repositioning, the software produces more efficient toolpaths, extends tool life and significantly reduces cycle times. No additional optimization is required."

VoluMill for GibbsCAM works on any combination of part and stock boundaries, and supports an unlimited number of islands, walls, pocket depths and island heights. According to the company, some of the additional contributors to faster removal rates, longer tool life and shorter cycle times include:

- Programmed rate of material removal to keep tool and workpiece temperature consistent, dissipating heat with chips

- Automatic feedrate and depth of cut adjustment to maintain programmed material removal rate, eliminate excessive loading and minimize tool wear, heat build-up and vibration

- Intelligent side milling and slot milling (with programmer override) to provide fast cycle time, with automatic feedrate and Z-depth adjustments in slot milling for constant material removal

- Smoothing radius to maximize tool utilization and minimize cycle time

- Contour ramping to maximize removal in tight areas, while minimizing cycle time

- Up to 100% step-over help to ensure complete clean-up

- Clean-up milling to allow a smaller tool to remove material left by a larger tool

- High-speed repositioning, with minimal clearance and no tool drag across floor.

Southwest

For more information contact:

Jason Heyse

Texas Offline Inc.

281-376-2003

sales@texasoffline.com

www.texasoffline.com

Southeast

Yvonne Anderson

Gibbs & Associates

323 Science Dr.

Moorpark, CA 93021-2092

805-523-0004

yvonnea@gibbscam.com

www.gibbscam.com

Northeast

Yvonne Anderson

Gibbs & Associates

323 Science Dr.

Moorpark, CA 93021-2092

805-523-0004

yvonnea@gibbscam.com

www.gibbscam.com

Midwest

Yvonne Anderson

Gibbs & Associates

323 Science Dr.

Moorpark, CA 93021-2092

805-523-0004

yvonnea@gibbscam.com

www.gibbscam.com

West

Yvonne Anderson

Gibbs & Associates

323 Science Dr.

Moorpark, CA 93021-2092

805-523-0004

yvonnea@gibbscam.com

www.gibbscam.com

< back