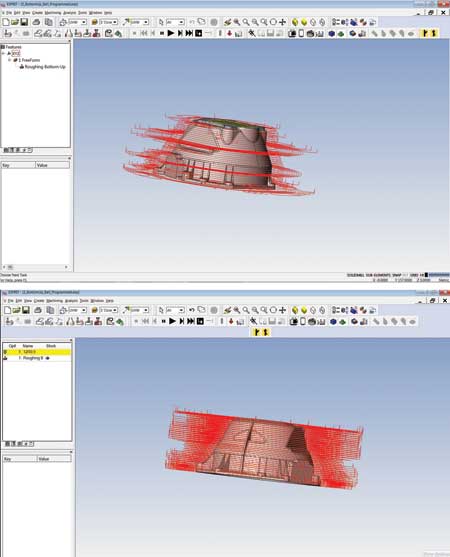

Comparison of tool paths between bottom-up roughing (top) and top-down roughing (bottom).

Bottom-up roughing strategy, Step 1: Incremental depths start at the first maximum vertical plunge and increment upward.

Bottom-up roughing strategy, Step 2: The second maximum depth is followed by incremental depth passes from the bottom toward the top.

Roughing is one of the fundamental technologies used to remove a substantial amount of material in the initial stage of production for both complex machining and single-channel operations. "In the machining industry, having a strong roughing strategy can be the determining factor that gives CAM users the ability to achieve maximum productivity while reducing overall costs," said a DP Technology spokesperson.

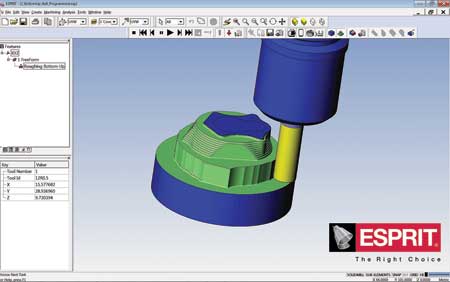

ESPRIT 2015 offers advanced machining technology with new strategies in roughing cycles such as blade and port roughing in 5-axis and bottom-up roughing in 3-axis. "Rather than traditional top-down strategy, bottom-up roughing allows users to take the full depth of a cut in the first pass," said the spokesperson.

"Using ESPRIT 2015's new bottom-up roughing strategy, CAM programmers will benefit from a dramatic reduction in roughing cycle time and a noticeable improvement in tool life," said Cedric Simard, Global Marketing Director of DP Technology. "This strategy lets you attain a small residual stock height on the part surface during the stock removal process. It can be combined with Profit Milling - our unique high-speed machining roughing technology - for major improvement in overall productivity. Profit Milling optimizes engagement angle, chip load, lateral cutter force and machine acceleration to achieve optimal results." ESPRIT 2015 also includes other new features and enhancements in 3-axis, 5-axis, milling, data exchange and simulation.

Complex Machining

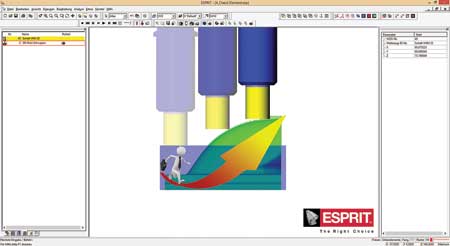

ESPRIT 2015 offers features in 5-axis that are designed to make complex machining more efficient and allow users to have more tool path options with features such as blade roughing and chamfering. "ESPRIT 2015 blade roughing enables users to remove material down to uniform stock around the blade and eliminates the need to follow semi-finish cycles," said the spokesperson. "Users in the aerospace, energy, medical and automotive industries will benefit the most from these time-saving operations for precision parts."

Enhanced WorkFlow

According to the company, ESPRIT 2015 enables users to gain control of the programming output by providing stock automation technology in facing, contouring, and pocketing operations. "Stock automation comes with improved recognition of materials removed from previous operations, which gives the user more control and awareness of the process," said the spokesperson. "This ultimately provides a smoother transition between diverse operations resulting in a consistent workflow with fewer interruptions."

CAM Programming

The improvement of feature recognition in ESPRIT 2015 is designed to allow users to create features based on solid models rather than geometry. "In addition, ESPRIT enhances the capability on solid models to avoid openings by covering or connect faces, to extend faces on broken edges, to merge faces for difficult areas and to apply operations," said the spokesperson. "Rather than importing just the model, users can now import sketches for a better understanding of the design."

For more information contact:

Charles Mathews

Vice President

DP Technology Corp.

1150 Avenida Acaso

Camarillo, CA 93012

805-388-6000

esprit@dptechnology.com

www.dptechnology.com