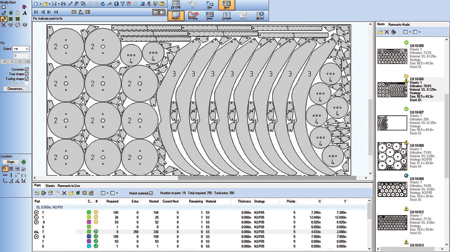

One of the reasons Alcon chose Radan is because the solution allows users to modify automatically-generated nests for greater programming flexibility.

While one of Radan's strengths is the generation of highly efficient nests, the system enables users to edit any nest, which ensures that the user retains control.

Alcon Tool produces industrial cutting tools for a variety of sectors, including food processing and textiles.

Tim Cummings at work on the shop floor at Alcon Tool, which remains competitive by consistently integrating new technologies for greater efficiency and material yield.

"We wanted usability for operators to be able to nest while running another machine, and without needing to have a PhD in manufacturing to accomplish that," said Engineer Dan DeBellis, Alcon Tool.

"Radan was able to beat everyone else with an average of 10% better sheet utilization," said Engineer Dan DeBellis, Alcon Tool.

An assortment of parts produced by Alcon Tool, which manufactures industrial cutting tools.

(l-r) Tim Cummings and Dan DeBellis on the shop floor at Alcon Tool with a challenging nested part.

Being competitive for the long haul is a challenge for any manufacturer, which is why Alcon Tool stays ahead of the game by implementing new technologies to increase efficiency and material yield.

Based in Akron, OH, the 72-year-old company produces industrial cutting tools for a variety of sectors, such as food processing and textiles. Blades designed to slice through steel or rubber are among those in which the company specializes. Customers can order from a line of about 20 existing products, or request custom designs, which are produced by the company's engineering department.

Because production often entails working with expensive materials, including stainless steels and tool steel, manufacturing can be challenging and missteps quite pricey.

"We can make whatever our customers can imagine, and in terms of size, we run the whole gamut," said Engineer Dan DeBellis, who has been with Alcon Tool for a decade. "We make things from as small as 1 inch x 1 inch all the way up to a 25- or 30-inch diameter, and most everything we make is mounted in some kind of industrial machinery."

DeBellis attributes the company's staying power to its customer service, product quality and the strength and creativity of its management. "Our customer service, our understanding of industrial cutting tools and the quality that we can achieve on site are some of our strengths," he said, noting that being able to keep about 95% of production in-house gives the company significant control over its own needs.

"We get to be very creative on a daily basis because we are always trying to be better and more efficient-and we always have more work that we can deal with, all from word-of-mouth marketing," said DeBellis.

Alcon's overarching goal for ever-greater efficiency led to the purchase in 2017 of the Radan CAD/CAM solution, by Vero Software, which is designed specifically for the processing of sheet metal products. The decision to implement the software was linked to the purchase of a 2-D laser, the programming of which required a powerful solution.

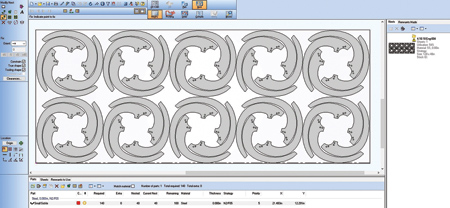

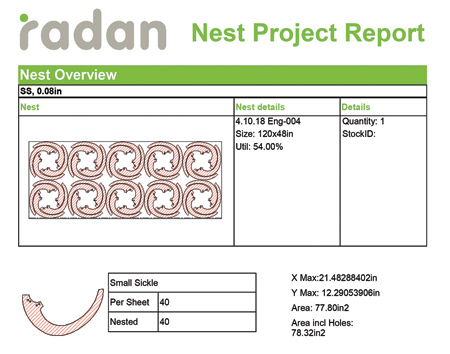

"We decided to bring our 2-D laser cutting in house, and part of that process was having a robust nesting software system," DeBellis said. "We found what we felt were the top three nesting companies out there today, and ran them through a range of tests to see which software could nest most efficiently."

Each of Alcon's contenders was tasked with programming and nesting a complex, asymmetrical, semi-sickle-shaped part. "To nest it, you really have to come up with some creative solutions," DeBellis said. "Radan was able to beat everyone else with an average of 10% better sheet utilization. We were hoping to get 1 or 2%, but 10% was a huge jump forward. On top of that, it had a very efficient nest in under 10 seconds."

DeBellis noted that any boost in sheet utilization can quickly add up to considerable savings due to high sheet costs. "If we can save 10%, that is a huge advantage for us, but it can often save us even more than that. Our new projected savings is 10 to 20% in our sheet purchasing."

In addition to the strength of Radan's nesting engine, the team at Alcon was in search of a solution that is easy to learn and to use, and that would enable shop floor staff to more easily multitask. "We wanted usability for operators to be able to nest while running another machine, and without needing to have a PhD in manufacturing to accomplish that," said DeBellis.

While one of Radan's strengths is in the generation of highly efficient nests, the system's built-in flexibility enables users to edit any nest, which ensures that the user retains control.

"Automatic nesting is a better way of nesting than I could ever do myself, but occasionally I go in and change them," DeBellis said. "That was something that Radan's competitors did not offer: the ability to modify an existing nest. You could not change anything, but had to either take it or leave it. For us, flexibility is key."

Radan created efficient nests by analyzing the true shape, material and thickness of all components in a batch, separating and sorting automatically to produce high utilization, manufacturable nests from sheets, off-cuts and remnants.

"We did our homework and went with a company that would be a home run for us," DeBellis said. "We are very impressed with how we are able to get to usable products with Radan."

Being able to rapidly create nests and see a return on investment was vital for Alcon, so it was important that the company had the support it needed to quickly put Radan to use. DeBellis said that the company had the support it required to fully utilize the new solution.

"The training process was really thorough and robust, and it made it seamless for us as a company to go from not nesting to cutting products that we are able to sell," he said. "For us at Alcon, having a salesperson that we can develop a relationship with is very important; we were very aware that we are moving forward with the support we required."

For more information contact:

Alcon Tool Company

565 Lafollette Street

Akron, OH 44311

330-773-9171

sales@alcontool.com

www.alcontool.com

Vero USA Inc.

2000 Town Center

Suite 1730

Southfield, MI 48075

248-351-9300 / 800-280-6932

info@verosoftware.com

www.verosoftware.com