Rust Inhibitor Passes All Tests at the Welder Training and Testing Institute

November 1, 2018

Tensile Strength Test

Fluoramics, Inc., a manufacturer of sealants, greases and rust inhibitors, has reported that its HinderRUST S4.0 rust inhibitor has passed extensive weld testing at the Welder Training and Testing Institute (WTTI) in Allentown, PA. The testing results showed that welders can weld steel directly through this HinderRUST formulation.

HinderRUST S4.0 is suitable for the metal fabrication industry to prevent corrosion of steel. Solvent-free S4.0 can be applied to steel parts or plates by brush, roller or aerosol spray can, and it will immediately displace moisture on the treated surface and protect the steel from rust for up to two years.

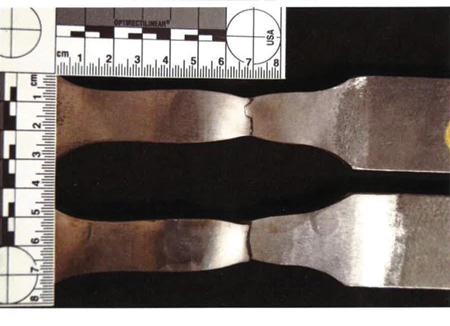

To determine if strong, secure welds can be made to steel treated with S4.0, the WTTI conducted a series of tests on A/SA516 Grade 60/70 steel of a uniform thickness of .375". As a first step, WTTI brushed on a thin layer of S4.0 to a series of steel specimens, and then proceeded with welding. Once the welds were completed, WTTI conducted guided bend tests (IAW-BT1), tensile tests (IAW TT-1) and visual and radiographic inspections of the welded specimens to affirm their strength and integrity. All tests were conducted in accordance with ASME Section IX -2017.

The steel specimens treated with HinderRUST S4.0 passed every test without fail: two transverse face bends, two transverse root bends, two tensile strength tests and all visual and radiographic inspections. In the case of the tensile strength tests, the two samples withstood 82,558 PSI and 78,244 PSI loads, respectively, before the steel failed outside the weld areas. The complete WTTI test report can be viewed at www.fluoramics.com/testing/weld-through-testing-on-hinderrust-s4-0/, or requested by phone.

For more information contact:

Fluoramics, Inc.

121 Steuben Street

Winona, MN 55987

507-205-9216

preick@fluoramics.com

www.fluoramics.com

< back