New Capabilities for RPC Systems

March 1, 2015

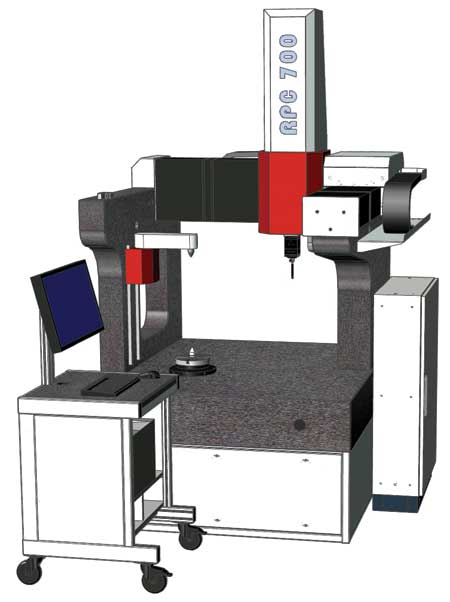

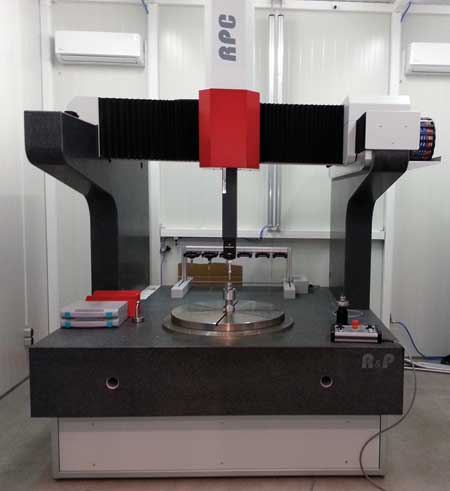

RPC 700

RPC 1000/1600 with workpiece

R&P Metrology GmbH has announced new capabilities for the entire line of RPC measuring systems (RPC 700, RPC 1000 and RPC 1600), as well as all custom and special systems in the R&P Metrology lineup. These form and profile measuring systems are all also capable of fully generative gear inspection.

The RPC 700 is designed for accurate profile and form measurements on rotationally symmetrical workpieces, such as bearing rings and races, as well as demanding aerospace and cylindrical workpieces. According to Hans Rauth, President of R&P Metrology, "This 4-axis machine utilizes the highly accurate air bearing, direct drive rotary table to measure form and profiles along with true generative gear measuring. Our use of linear motor technologies and granite air bearing guide elements provide wear-free, consistent and thermally stable measurements."

All RPC systems are I++ compatible, allowing a variety of CMM software packages from various suppliers to be supported. A tailstock is offered as an option on the RPC 700.

The RPC systems are now available in three standard sizes, with the RPC 700 able to accommodate workpieces up to 700 mm in diameter. The linear travels are 600 mm, 700 mm and 500 mm (XYZ). Parts up to 300 kg are accommodated on the rotary table. The larger RPC 1600 handles 1,600 mm parts and increases the X-axis travel to 900 mm. The RPC 1000 is also available, with a maximum diameter of 1,000 mm. Nearly any custom and special requirements can be met.

Support, service and sales for North America is provided by Kapp Technologies.

For more information contact:

Dwight Smith, Sales Manager

KAPP Technologies

2870 Wilderness Place

Boulder, CO 80301

303-447-1130

info-usa@kapp-niles.com

www.kapp-usa.com

< back