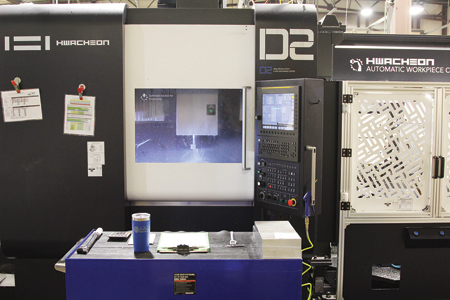

Hwacheon D2-5AX with 8-station pallet pool

Universal Robots UR10e attached to YCM XV1250a VMC, awaiting material.

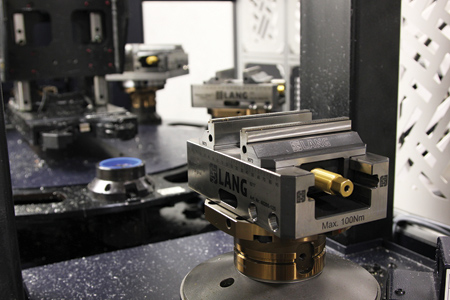

Lang Makro-grip self-centering vises for long parts

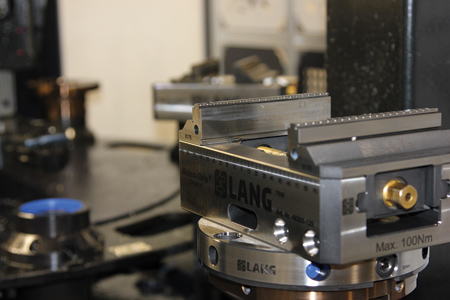

Single Lang Makro-grip vise on quick change plate for faster fixture changes

Sam Hartwig, Production Manager/Senior Machinist, loading stock through the workpiece changer for production.

Multiple fixture set-ups ready for production in the workpiece changer.

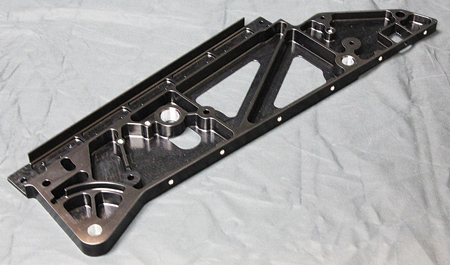

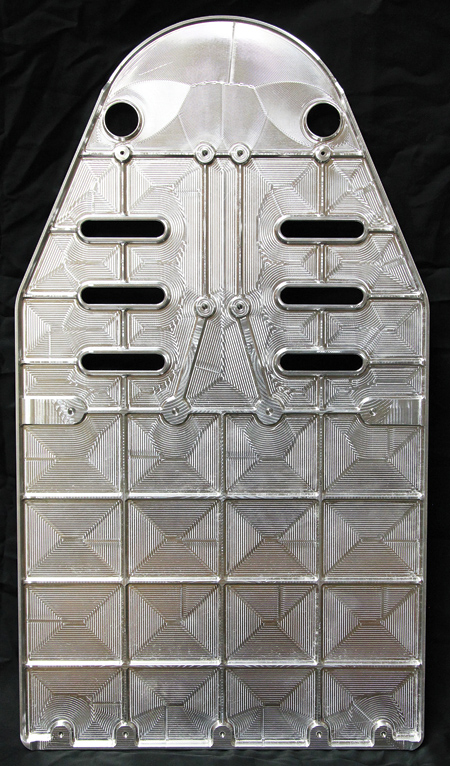

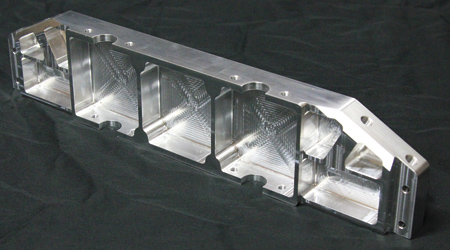

Components machined on the Hwacheon D2-5AX.

A.N.S. Machine LLC is a Tier 1 supplier for a wide range of industries, including aerospace, medical, recreational and consumer products. Recently, the company made the decision to increase efficiency and accuracy with the addition of high precision technology.

"Coming into 2020, we realized the aerospace products we were manufacturing were becoming too difficult to accurately and efficiently manufacture on our standard 3-axis vertical mills," said Sam Hartwig, Production Manager, A.N.S. Machine. "There has also been notoriously short supply of qualified machinists able to do the work we do. With these things considered, we started looking into 5-axis mills with automation."

After careful consideration, A.N.S. Machine selected the Hwacheon D2-5AX with an 8-station pallet pool. "Talking with the local distributor, Premier Machine Tool, we felt extremely comfortable with their ability to service us when the need arises, and the applications engineer was top notch," said Hartwig. "We were comfortable running the new technology nearly the first day of training."

Hartwig said the solution is working better than they had imagined. "It solved problems we did not even know we had," he said. "The productivity has been 8x more efficient than running these parts in our 3-axis mills with no automation. With the new 5-axis mill, five or more sides are machined in one workholding off of one work offset, keeping everything perfectly in tolerance."

The Hwacheon D2-5AX is equipped with an acceleration/deceleration conveyance system design, and the structure allows easy access to robots and multi-pallet systems. It can machine products that require simultaneous 5-axis machining or have complex shapes requiring multiple processes with one set-up.

D2-5AX has a cooled spindle, a 60-tool capacity tool carriage, 12,000 RPM spindle and 4+1 machining capability. A.N.S. Machine chose to utilize the 8-station pallet pool.

According to Hartwig, most set-up times have gone from 4 to 8 hours and 4 to 6 operations down to about 3 hours and two operations. "Holding the part once and machining five sides in a single operation has made inspection effortless because the parts have become so much more accurate," he said. "On one specific job, the scrap rate has gone from highest of 3% to a .5% average."

A.N.S. machines aluminum, steel, stainless steel and nylon 6/6. The company manufactures mostly aerospace interiors, but also manufactures products for food packaging, paper machine components, agricultural components, prototype and production.

In addition to the Hwacheon, the A.N.S. lineup includes:

- YCM XV1250A vertical 20x50 work envelope with UR10E cobot

- YCM XV1250A vertical 20x50 work envelope

- Three YCM XV1020A verticals with 17x40 work envelope

- Twinhorn 1010 vertical 17x40 work envelope

- Chevalier QP2040-L vertical 20x40 work envelope

- Supermax FX102A vertical 17x40 work envelope with two-station pallet changer

- Yang ML-15A bar fed turning center

- YCM GT-200 turning center

- Round tube finishing machine .5" to 4" diameter

- Faro arm CMM

- Keyence instant measuring machine

- Full line of high precision pins and thread gauges

- GibbsCAM CAD program.

Jeff and Julie Hartwig opened A.N.S. Machine in August 1995. The company has seen consistent growth, and in 2008 moved into the Peshtigo Industrial Park in Peshtigo, WI. The company received its ISO-9001:2015 certification in April of 2011, and in 2016 became AS9100 certified.

For more information contact:

Sam Hartwig

Production Manager

A.N.S. Machine LLC

940 Pine Street

Peshtigo, WI 54157

715-582-0461

sam@ansmachine.com

www.ansmachine.com

Hwacheon Machinery America

555 Bond St.

Lincolnshire, IL 60069

847-573-0100

www.hwacheon.com

Premier Machine Tool Midwest

P.O. Box 102

Hartland, WI 53029

414-254-5150

www.pmtmidwest.com