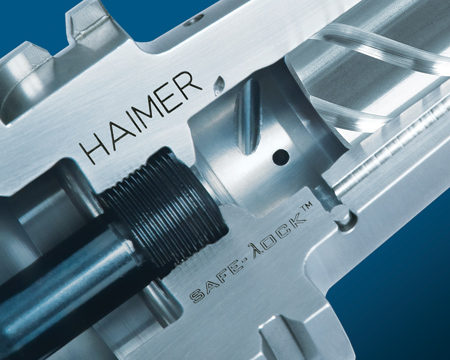

Haimer Safe-Lock Tool Clamping System

HAIMER, headquartered in Igenhausen, Germany, has developed a toolholding system for high-performance machining called Safe-Lock.

The new HAIMER Safe-Lock System is a clamping tool specifically engineered to overcome micro-creep in order to enhance High Performance Cutting (HPC). Safe-Lock's development can be attributed to the rising demands of heavy duty machining, common in the aerospace and mold & die industries. Advanced materials, such as titanium alloys, are lightweight, high-strength, corrosion-resistant and difficult to machine. Machining these materials is possible by means of HPC, which generates high cutting forces. These forces often cause the cutting tool to rotate in the toolholder, which can slowly pull the cutting tool out of the chuck. "Micro-creep especially applies to toolholders offering precise clamping and good runout accuracy, such as shrink-fit, hydraulic or milling chucks," said a company spokesperson.

The Safe-Lock system combats micro-creep with its patented design. The Safe-Lock principle works like this: spiral-shaped grooves integrate into mating carbide drive pins in the toolholder, combining frictional clamping force and positive locking, designed to eliminate micro-creep. "This allows for increased cutting depths and feedrates and doubles metal removal rates by allowing cutting at higher RPM. Additionally, this unique system provides the best runout accuracy via a naturally concentric design, decreasing tool wear significantly," said the spokesperson. Machinists can use the Safe-Lock system to prevent micro-creep in roughing and trochoidal milling applications.

HAIMER has many Safe-Lock licensed partners including Data Flute, Emuge Franken, Helical, Kennametal, Melin Tool, Niagara Cutter, OSG, Sandvik Coromant, Seco, SGS, Sumitomo, Walter Tools and Widia. The system is integrated and available in both shrink fit and collet chuck tool holders, in a variety of sizes and taper configurations.

For more information contact:

HAIMER USA

134 E. Hill Street

Villa Park, IL 60181

630-833-1500

haimer@haimer-usa.com

www.haimer-usa.com