EWI has added direct metal laser sintering to its additive manufacturing capabilities with the acquisition of the EOSINT M 280 system.

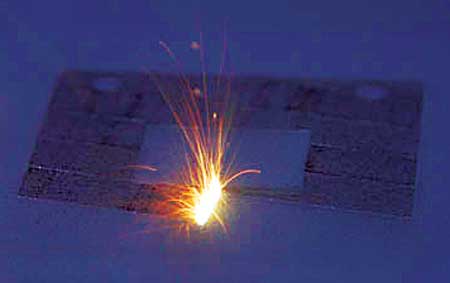

DMLS technology in action: a complicated metal part is fabricated quickly and precisely.

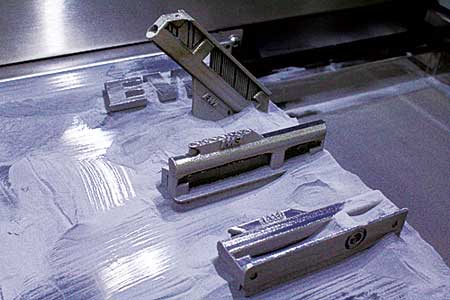

Complex, custom-designed components can be created using the DMLS powder-bed system.

With the addition of a high-performance EOS direct metal laser-sintering (DMLS) system at its technology facility, EWI now offers manufacturers 3D metal printing services supported by the company's technical expertise in materials joining.

The EOS DMLS system features additive manufacturing technology with the capacity to fuse metal powder into 3D components.

The organization, which has long been engaged in the development of additive manufacturing through both its Additive Manufacturing Consortium (AMC) and its spinout company Fabrisonic LLC, will apply the state-of-the-art EOSINT M 280 system to further advance additive manufacturing technology and provide additional metal manufacturing solutions to OEMs and suppliers, according to a spokesperson.

Through a joint partnership agreement, EWI will serve as a preferred materials development partner to EOS of North America, Inc. to create new additive manufacturing solutions from metal alloys that are not currently available. "This partnership is a natural fit," said Tim Morris, Vice President of EOS North America, Inc. "Our laser sintering technology enables the manufacture of complex metallic components through laser joining, and EWI has a strong industry focus and critical expertise in process and materials interaction, as well as additive manufacturing."

EWI President and CEO Henry Cialone said, "By combining our experience in laser optics, materials science and process controls with the laser powder bed fusion technology of the EOSINT M 280 system, we will be able to help our customers manufacture parts more effectively and efficiently than ever before."

For more information contact:

EWI

1250 Arthur E. Adams Drive

Columbus, OH 43221-3585

614-688-5000

www.ewi.org