Horizontal, Inverted, Submerged Fast Wire EDM

July 1, 2023

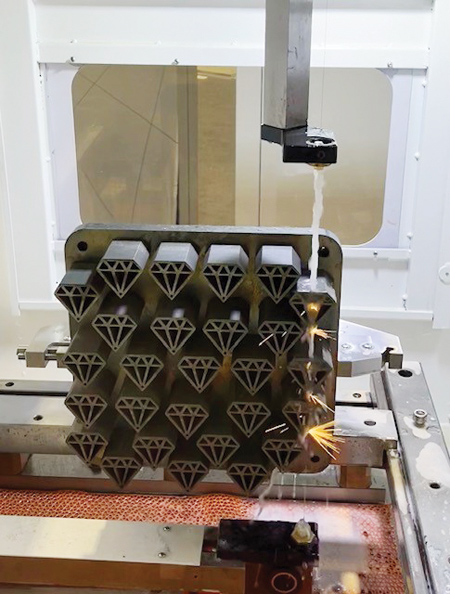

Demo part (shown vertically for detail)

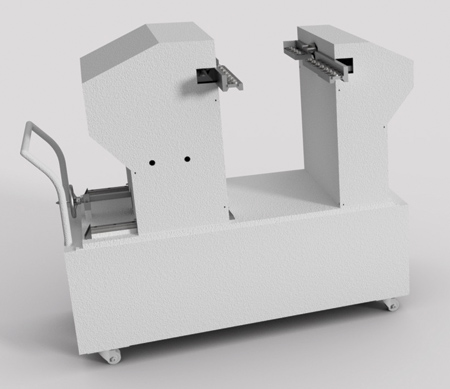

EDMMax FC (shown without machine cover for detail)

An optional loading cart is available.

EDMMax FC with optionally available loading cart.

EDM Network has introduced the EDMMax FC45HW/FC64HW. These inverted, submerged-cutting fast wire EDMs are designed to rapidly remove 3D metal printed parts from build plates.

The FC models were designed to operate with reusable brass or molybdenum wire, travelling back and forth between two spoolers at about 5 meters/second. The fast-moving wire draws the EDM swarf out of the cut area quickly to increase forward cutting speed. Fast wire EDMs are especially suited for the interrupted cutting of 3D metal printed parts as the fast-moving wire does not require high-pressure water for speed.

Part retrieval is simple with the drop front door design. FC models cut with the build plate inverted so that upon cutoff, the individual parts separate and float to the bottom of the work tank for easy retrieval.

"The FC models are of stainless steel design and therefore only require deionized water without the additive used by other fast wire EDMs, eliminating the secondary cleaning operation," said a spokesperson.

Additional features and benefits:

- Reusable 0.012" brass or molybdenum (moly) wire

- AC and DC switchable power supplies

- Automated build plate loading cart (optional)

- Max. table load for heavier build plates: Up to 176 lbs. (FC45HW) and 440 lbs. (FC64HW)

- Zero-point clamping to help ensure accuracy

- Alignment of wire to build plate

- Tension control by servo motor

- Fast changing of new wire (approx. 250 meters)

- Available in two sizes to accommodate build plate sizes: 400 mm x 400 mm / 650 mm x 650 mm

- On site set-up and training included

- Made in Taiwan.

For more information contact:

EDM Network, Inc.

1974 Bucktail Lane

Sugar Grove, IL 60554

630-466-5588

info@edmnetwork.com

www.edmnetwork.com

< back