Software for Programming Simultaneous Motion

October 1, 2014

Mastercam Swiss Expert now offers support of 5-axis Swiss machines in the market, making the complex task of programming 5 axes of simultaneous motion simple, according to the company.

Mastercam Swiss Expert lets users simulate a project on a virtual machine before it reaches the shop floor.

"With the new class of complex machines, manual programming is no longer efficient or even feasible with some designs," said a CNC Software, Inc. spokesperson. "Mastercam Swiss Expert now offers support of the 5-axis Swiss machines in the market, making the complex task of programming 5 axes of simultaneous motion simple. This support allows designers more freedom to add increasingly complex features."

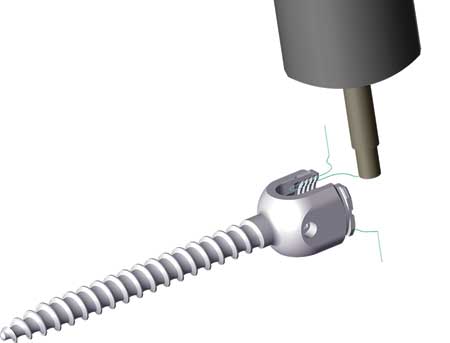

Solids Programming

Mastercam Swiss Expert is completely solids based, allowing for quick toolpath creation from solid faces, edges, loops and turned profiles. There is no need to create additional geometry to cut a part.

Tools to Make Programming Easier

According to the company, Mastercam Swiss Expert gives users a set of tools that impact the entire process, including:

- A complete understanding of the machine allows for streamlined programming, from toolpaths to synchronization to simulation.

- Select tools and build 3D tool assemblies in the comprehensive Tool Manager. Tools, tool assemblies and tool equipment are fully supported in Machine Simulation.

- Save tools and cutting strategies into libraries for future use on similar or families of parts.

- View operations and add synchronization points graphically using the Sync Manager. Mastercam Swiss Expert will prevent adding sync points that the machine cannot execute.

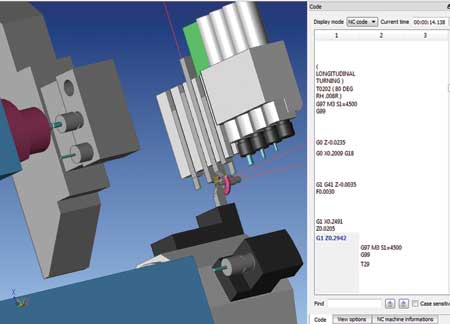

Simulation

Mastercam Swiss Expert lets users fully and safely simulate projects on a virtual machine before it reaches the shop floor. Mastercam Swiss Expert's simulation provides:

- Full simulation of every moving component of the machine, including material, main and sub spindles, all toolholders and part handling devices.

- Automatic collision detection catches collisions in a virtual environment before damaging expensive equipment.

- Accurate machine models are designed to allow users to be confident in the representation of machining processes.

- Automatically jump to any point in the simulation by selecting a location on the Gantt chart.

- Simultaneously view NC code for all channels while simulating a part.

Synchronization

Mastercam Swiss Expert has all of the tools necessary to graphically optimize part cycle times and avoid collisions, according to the company. With the Sync Manager, users can:

- Use an unlimited number of channels.

- Drag, drop and sync operations to one another.

- Sync operations by tool group or by channel.

- View all machining parameters and modify them on-the-fly if necessary.

- Expand and contract the timeline for trouble-free viewing of the part process.

- Use colors to help identify which toolpaths belong to which tool group or channel.

- Quickly view the time each operation takes to complete.

For more information contact:

Michelle Nemeth

CNC Software, Inc.

671 Old Post Road

Tolland, CT 06084

860-875-5006

info@mastercam.com

www.mastercam.com

< back