Lasers Cutting Blanks for the Smart Press Shop

November 1, 2021

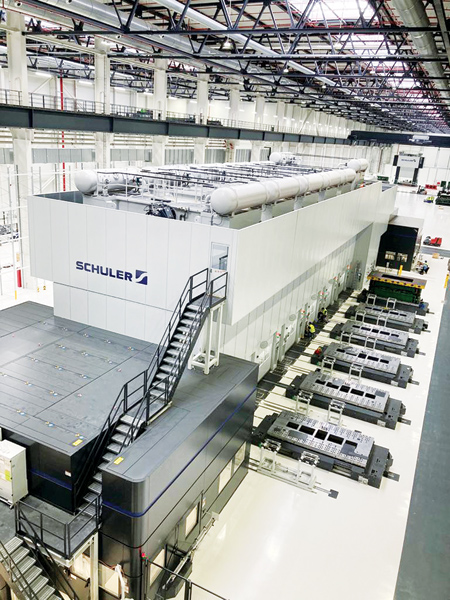

The Laser Blanking Line 2.18 does not require any blanking dies and produces blanks from the continuously moving strip.

The Laser Blanking Line 2.18 supplies the blanks for the servo press line in the Smart Press Shop with an output of 20 strokes per minute.

At the beginning of June, Porsche and Schuler began the operation of a fully-connected press shop in East German Halle (Saale). In addition to a servo press line with an output of up to 20 strokes per minute, the Smart Press Shop also features a state-of-the-art blanking line: a Laser Blanking Line 2.18 equipped with two cutting heads for processing strip material with a width of up to 1,880 mm.

"Blanking lines with lasers do not require expensive and heavy blanking dies, which is why they are particularly suitable for the production of new parts or small batch sizes with frequent product changes," said a company spokesperson. The continuously moving coil material is processed into blanks at high cutting speeds. Due to tooling-free scrap separation, a high output is also achieved as well as gentle transport of sensitive materials, such as aluminum.

The Laser Blanking Line is suited for the Smart Press Shop in Halle, which focuses on the production of aluminum outer skin parts in small batch sizes. By recording various measured values of the system as well as the coil material and by smart marking of the blank, the line that supplies the blanks for the servo press line forms the point of departure for a Track and Trace system.

For more information contact:

Schuler Inc.

7145 Commerce Blvd.

Canton, MI 48187

734-207-7200

info@schulerinc.com

www.schulergroup.com/laserblanking

< back