Laser System for Measuring Diameters of Ground Parts

November 1, 2020

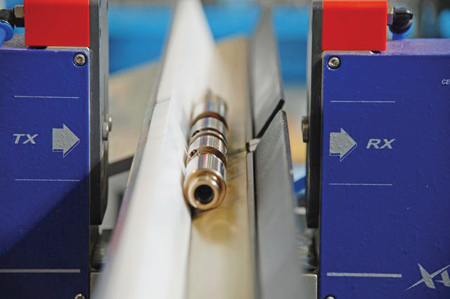

Marposs' Aeroel Grindline Laser System for measuring the outer diameter and taper of ground parts.

Marposs has announced its Aeroel Grindline Laser System designed specifically for measuring the outer diameter and taper of parts finished by through-feed or plunge centerless grinders, such as electric motor shafts, shock absorber rods, pins, steering racks and more. Grindline enables 100% inspection, detecting out-of-tolerance parts to reduce scrap and labor costs while improving quality.

The Grindline+.X software relies on an Xactum laser gauge installed at the output of the grinder for measuring parts after the machining process without the need for stopping production. The ground parts, after being cleaned, pass through the laser beam where hundreds of measurements are recorded along the axis of the piece and processed by the software. The measured diameters are displayed and compared with the pre-set nominal value. If the process drifts beyond the pre-set control limits, the Grindline software automatically compensates for wear of the grinding wheel to keep the product within the desired tolerance limits. The collected data can be processed in real time or downloaded to a remote computer.

The exclusive data processing software, featuring automatic shape recognition of ground parts, can gauge up to 10 different diameters on components while ignoring all shape irregularities that could compromise measurement results. "Chamfers, grooves, threads, through holes or drops of emulsion on the workpiece are unable to deceive the system," said a company spokesperson.

Grindline systems feature Aeorel's exclusive NO-VAR Technology, which prevents measuring drift due to changing room temperature. Standard systems come with an Xactum laser gauge, CE-200 operator's interface panel with LCD display, 19" rack mount version, pre-installed Grindline+.X software and a 5 m long connecting cable. Depending on the system, measuring fields are available up to 40 mm or 80 mm, measuring diameters from 0.06 mm to 38 mm or 0.75 mm to 78 mm, with a repeatability of ±0.1 mm or ±0.3 mm.

For more information contact:

Marposs Corporation

3300 Cross Creek Parkway

Auburn Hills, MI 48326

248-370-0404

marposs@us.marposs.com

www.marposs.com

< back