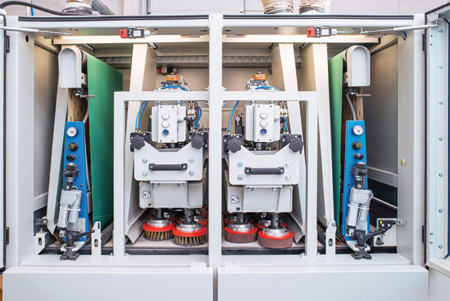

FINISHLINE finishing and deburring machines process part thicknesses up to 6.30" and automatically measure parts for optimal results.

FINISHLINE metal finishing machines are available in a variety of belt widths from 25.5" to 51" and come with two, three or four working units for an all-in-one deburring, graining, edge-rounding, oxide and slag removal and surface polishing solution.

Performance is within reach with ROLLON Sliding System making for easy quick and brush changes.

FINISHLINE's swivel touchscreen control panel provides flexibility for operators wherever they need it.

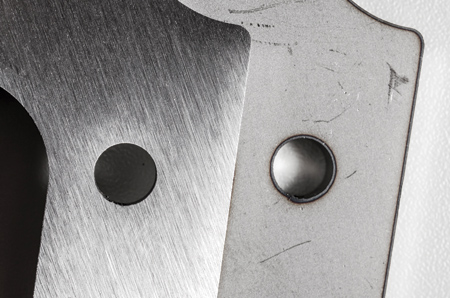

Before and after sample parts run on the FINISHLINE.

East Coast machinery distributor Southern States Machinery, Inc. will now be distributing FINISHLINE, a leading-edge deburring and finishing machine. This two, three or four working unit machine is available in both standard and customized variations with working widths of 25.5" to 51" for large parts or small parts. With FINISHLINE, metal fabricators will be able to complete deburring, graining, edge rounding, oxide and slag removal, as well as surface polishing for parts originating from lasers, plasma systems, waterjets or punches in one process.

"We are continually working to change the way people think about secondary processes. Finishing does not have to be manual or inconvenient," stated President Kevin Kilgallen. "This machine is going to be the answer for metal fabricators who are motivated to improve upon operational efficiency and part consistency."

In addition to standard and customized options, FINISHLINE features automatic part measurement to ensure easy and accurate set-ups for minimal rework, intuitive 7.5" touchscreen swivel controls for operator ease of use and programming as well as quality systems with name brands such as Schneider Electrics and Rollon Sliding System.

Southern States Machinery will also provide installation and maintenance support directly from its in-house technical service and application engineering team.

For more information contact:

Southern States Machinery

128 Cayuga Drive

Mooresville, NC 28117

800-540-9713

www.southernstatesmachinery.com

Southern States Machinery

8374 Market St., #430

Bradenton, FL 34202