Together with a series of partners for tools, clamping materials and automation solutions, the DMG MORI Automotive Excellence Center provides its customers with a holistic range of services from a single source.

The CTV model series is a solution for automotive components in vertical production turning.

Kingpin VL, CF53 carbon steel: 1) Machining of bearing track, o18 mm ball dia., 30 sec. machining time; 2) gearSKIVING of the gear, spur gearing module 0.8, 20 sec. machining time

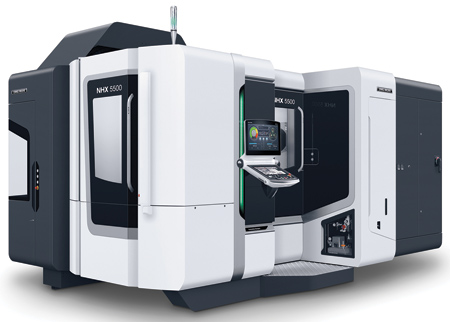

Among other things, battery boxes for hybrid and electric vehicles are manufactured on the NHX 5500.

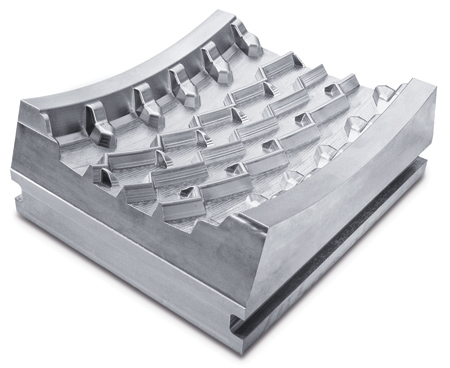

The scope of services of the DMG MORI Automotive Excellence Center includes the manufacturing of molds for body components. Tire mold shown.

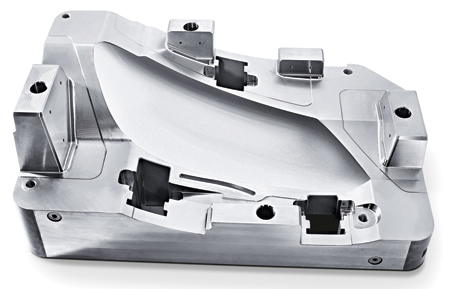

Injection mold headlight

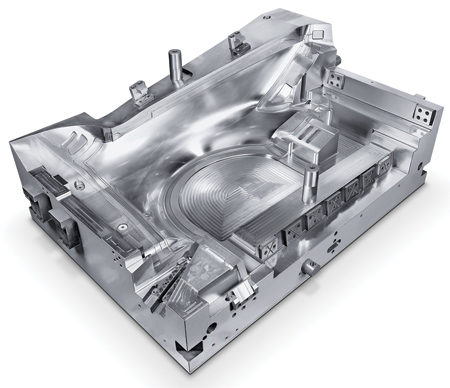

Pressing tool for mudguards

The model ranges of car manufacturers now include increasing numbers of hybrid vehicles and electrically powered cars. This change is also affecting the range of components in the automotive area. This new model diversity requires flexible and efficient manufacturing solutions, both for large production runs and also smaller batch sizes. As a partner to the automotive industry for many years, DMG MORI understands these requirements and implements holistic and fully automatic process solutions for car manufacturers and their suppliers in the DMG MORI Automotive Excellence Center.

With Technology Excellence Centers in key industries of aerospace, automotive, die & mold and medical, DMG MORI provides close collaboration with the customer during early project phases in order to implement optimum manufacturing concepts. For quite some time, the main focus in the automotive industry has not been on the machine tools alone, but holistic and highly automated process solutions. Together with a series of partners for tools, clamping materials and automation solutions, DMG MORI provides its customers with the entire range of services from a single source.

CTV Model Series: Compact Footprint, Integrated Automation

In view of the rapid change in the automotive industry, DMG MORI has reported equally rapid development of new components, for which it has developed efficient machines. The CTV model series features fast loading and unloading, a high degree of stability and powerful turrets with torque of up to 85 Nm.

The compact CTV models have integrated automation as standard. Other automation variants, such as accumulating conveyor belts and palette carousels, are optionally available. With the technology integration of grinding and gearSKIVING and a touch probe for quality assurance, DMG MORI has equipped the model series for the increasing complexity of the workpieces in a future-proof way.

With regard to the other model series in the turning area, Harry Junger, Managing Director of GILDEMEISTER Drehmaschinen, says the future is bright: "Our customers have been reliably manufacturing components such as constant velocity joints, drive shafts and planet carriers on our machines for years," he said. "These are also installed in electric vehicles, meaning we are still in a strong position for the requirements of the automotive sector."

This also affects the milling area. The wide range of products from Pfronten, Seebach and Japan includes productive manufacturing solutions for conventional drives and also hybrid and electric vehicles. For example, battery boxes are manufactured on the 5-axis machining centers in the DMU monoBLOCK and DMU eVo model series and the NHX 5500-fully automatic due to a wide range of workpiece and palette handling systems, which DMG MORI provides for all machine tools.

Highlights of the CTV 250 with CELOS V6:

- <12.5 sq. m footprint, including automation and chip conveyor

- 12 driven tools up to 85 Nm and 12,000 RPM

- Workpieces up to o350 mm x 200 mm and a Y-axis with 180 mm

- 8-second loading and unloading time due to two-track automation

- Direct measuring systems from MAGNESCALE in all linear axes

- New in CELOS: Automatic job import and application connector app.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

us.dmgmori.com