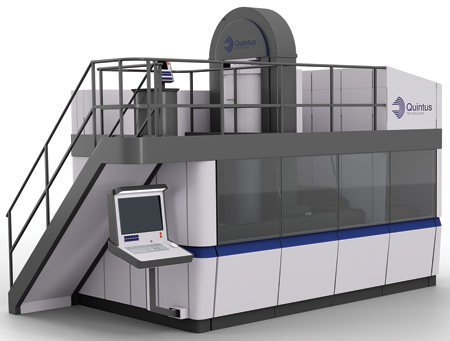

Configured as a space-saving Quintus Modularized Solution, FIT's HIP with Uniform Rapid Quenching will introduce a new benchmark in the quality of 3-D printed metal series parts.

A state-of-the-art hot isostatic press (HIP) with Uniform Rapid Quenching (URQ) from Quintus Technologies will introduce a new quality benchmark for the FIT Additive Manufacturing Group. Coming online in September 2019 in FIT's main facility in Lupburg, Germany, the press will enable the additive manufacturing (AM) specialist to boost productivity while nimbly responding to the heightened industrial requirements for 3-D printed metal series parts.

Operating at a temperature of 1,400 °C (2,552 °F) and pressure of 30,000 PSI (2,070 bar), the press model QIH 32 M URQ offers a capacity of 264 lbs. per load in a work zone that measures 270 mm (10.6") in diameter and 500 mm (19.7") in height. Its proprietary URQ feature allows heat treatment and cooling to be combined in a single process, known as high pressure heat treatment (HPHT). HPHT and HIP are used for the consolidation and densification of metal, ceramic and plastic parts, producing a maximum theoretical density, ductility and fatigue resistance in high-performance materials.

"The HIP addition reflects FIT's position as a pioneer of AM," said a company spokesperson. "Committed to radical innovation to expand the vast range of potential applications for 3-D printing, FIT has consistently been an early adopter of new technologies that offer production synergies, such as HIP and HPHT."

"We evaluated the requirements of 250 international industrial customers for five years, and HIP turned out as an answer to many quality issues," said Carl Fruth, CEO, FIT AG. "The results that can be achieved by combining AM and HPHT are highly encouraging. Our customers will benefit strongly from this partnership. I even think that all additive serial manufacturing will experience a big boost when integrating HPHT as a post-processing service."

Jan Söderström, CEO, Quintus Technologies, said, "We expect that the industrialization of AM in general will be revolutionized once HPHT post-processing is adopted by leading AM specialist FIT Additive Manufacturing Group. The overall optimization of process parameters and material-specific heat treatment parameters in an in-line, lean-process production context will lead to a new benchmark for dramatically optimized quality levels while reducing costs."

Further reinforcing the contribution of HPHT to the AM arena, the two companies have entered into a marketing agreement to expand adoption of the process. "In recognition that its HIP will become integral to production, FIT also opted for a five-year Quintus Care agreement. This rigorous preventative maintenance program optimizes press functionality at a fixed annual cost, offering FIT even more support in reducing operational risk while providing access to Quintus' vast HIP application knowledge," said the spokesperson.

"FIT was very intrigued by Quintus' ability to offer a complete partnership: the system itself, the Quintus Care program including application support, and the marketing agreement," Söderström said. "With this partnership we see the possibility to enter the market in the best possible way."

For more information contact:

Quintus Technologies LLC

8270 Green Meadows Drive N

Lewis Center, OH 43035

614-891-2732

info@quintusteam.com

www.quintustechnologies.com