Thread Repair Cycle Lathes

April 1, 2019

TUR630AMN overall: 25" swing x 118" BC with 5.5" spindle bore with manual tool post

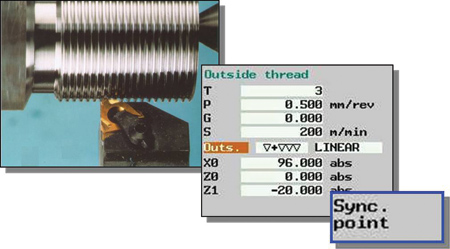

Siemens thread repair (re-cut damaged threads) cycle

Toolmex TUR European built lathes now offers enhanced threading and thread repair cycles on its TUR-MN flat bed lathes. "Incorporating the latest Siemens 840Dsl shop turn manual operate control makes these TUR our most flexible threading lathes," said a company spokesperson. These lathes are suitable in the oil & gas industry, large toolrooms or job shops requiring a wide range and quantity of threads on pipe, bar or shafts. "TUR with Siemens shop turn manual operate package is remarkably reliable, and ease of operation makes the TUR-MN a work horse in advanced plants around the world," added the spokesperson.

TUR-MN threading and thread repair cycle lathes are available with: from 40" BC (distance between centers) up to 393" BC with spindle bores from 4.1" - 17.7" diameter. "TUR lathes integrate the latest Siemens threading cycles with TUR modular design making them more universal than other flat bed threading lathes," said the spokesperson. TUR enhanced design addresses: guarding, controls, operator access to work for set-up, improves loading and unloading, shortens the learning curve, inch - metric threads and improve part finishes since operator can reduce chatter by changing the spindle speed while in the cut.

More TUR-MN features with the Siemens shop turn manual operate:

- Cut external threads, internal threads, taper threads and transversal (face) threads

- Threads can be single or multiple starts

- The tool infeed can be fixed depth, or degressive to keep the cuts cross-section constant (on progressive passes)

- Right-hand or left-hand threads, by the direction of rotation of the spindle programmed

- Thread infeed along one flank or alternating flanks to extend tool life

- Variable retraction distance

- Programmable run-in and run-out is designed to improve surface finish

- Rough and finish cycles, programmable as separate or combined

- Independent overhead mounted swivel control panel with dual Z & X mpg improves operator productivity

- Clear help instructions and color graphics assists machinist to review and debug a program.

Toolmex Lathes is the U.S. national importer for TUR European built lathes.

For more information contact:

Tom Kob

Toolmex Lathes

2015 S. Mitchell Blvd.

Schaumburg, IL 60193-4543

800-323-3480

machinesil@toolmex.com

www.toolmexlathes.com

< back