EMAG Technology Days June 6-7

May 1, 2018

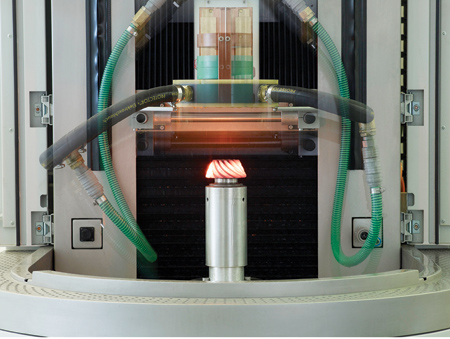

MIND-M 250

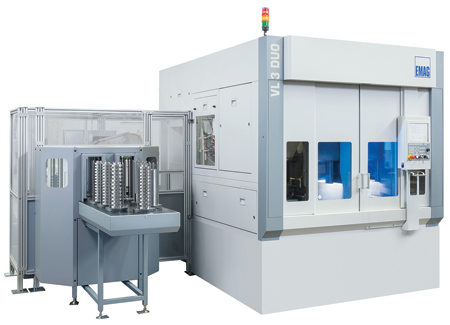

VL 3 DUO multi-spindle

VT 4 vertical lathe

VL 4 vertical turning center

EMAG L.L.C. will hold its annual Technology Days in Farmington Hills, MI (Detroit), June 6-7. On its first day, the event will run from noon-9 PM. On June 7, it will run from 8 AM-2:30 PM. The event will include a variety of machine tools under power for live demonstrations, plus a series of technical and market presentations by industry experts from the company. Topics will cover all the machining and joining technologies EMAG currently brings to the market, including vertical milling, ECM, laser and induction hardening.

The keynote presentations will be a discussion of innovative propulsion systems on June 6 and E-mobility trends and their impact on the traditional manufacturing landscape in the automotive supply chain on June 7. The event will be led by CEO of EMAG L.L.C. for North America, Peter Loetzner. Other featured speakers will be Michael Robinet from HIS Markit and Brett Smith from the Center for Automotive Research.

All interested parties are welcome to attend this event, at no cost. Visit techdays.emag.com to register. This microsite contains the full agenda of presentations, as well as the complete list of the equipment being demonstrated.

Production machine tools on display for live demonstrations or full inspection will include:

- VT 4 Vertical Lathe - Short cycle times, high precision and safe processing for shaft machining in the power transmission area. Short chip-to-chip times in 4-axis machining, workpiece grippers on two turrets and the EMAG vertical alignment technology that eliminates chip clusters in the machining area highlight this VMC.

- VL 4 Vertical Turning Machine - Increased flexibility and diverse manufacturing capabilities for soft and hard machining of components up to 200 mm diameters are offered by this advanced machine design. Interlinking of multiple machines for full production automation is also made possible with the flexible conveyor and workpiece chucking arrangements.

- VL 3 DUO Multi-Spindle Machine - This CNC machine is an efficient twin-spindle machine solution for chucked parts up to 150 mm in diameter and expands the EMAG offering in its VL Series. Each work area has its own spindle for independent operation and each tool turret has 12 positions, which can be loaded with live or static tools. It features EMAG TrackMotion for full automation, including part flipping between OP 10 and OP 20.

- VSC 400 Combined Turning and Grinding Center - Vertical turning and grinding in one machine, in a single set-up. Other modules can be attached for full turning, drilling, milling, grinding and even honing or hardening. Typical workpieces include gearwheels, chain wheels, sliding sleeves, CVT parts, conrods, rocker arms, bearing and piston rings. The small footprint machine design virtually eliminates the need for gantry loaders.

Also being shown in live demo mode is the EMAG MIND-M 250, a compact modular induction hardening machine.

EMAG engineers will be available to discuss the machines, the technologies and the Industry 4.0 services offered by the company.

For more information contact:

Kirk Stewart

Sales Director

EMAG L.L.C.

38800 Grand River Ave.

Farmington Hills, MI 48335

248-996-4703

kstewart@emag.com

www.emag.com

< back