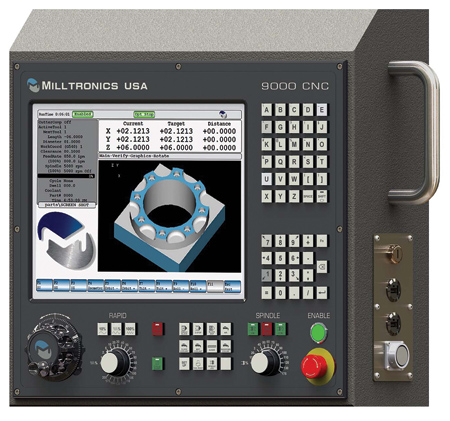

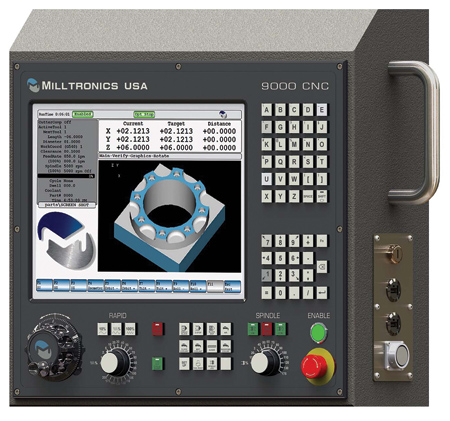

Milltronics Series 9000 CNC

Milltronics Shop View (MSV), an optional feature for the Series 9000 Control, is hosted in the cloud and can be accessed with a PC, tablet or smartphone.

Milltronics USA, Inc. offers the Series 9000 CNC as its latest PC-based control designed so anyone in the shop can program it. The Series 9000 can be programmed conversationally, with industry standard G- and M-codes or with toolpaths downloaded from a CAM system. The control is now available on Milltronics GP, IL and XP vertical machining centers (VMCs) and new SL-II Series of slant bed CNC lathes.

"With a 15 inch touchscreen, easy programming, on-screen help, intuitive menus, color graphics and prompted tool settings, the Series 9000 helps new operators train faster and become more productive sooner. The following features allow quick and confident operation of the CNC," said a company spokesperson. The features include:

- Solid model graphics allow operators to see a completed part prior to cutting. Milltronics intertwines its graphics with the motion system so the operator sees exactly what the machine is going to do (not just a picture of the part).

- Handwheel run allows the operator to run a program in a controlled mode where motion only occurs while the hand wheel is turning - allowing the operator to verify programs with total control and complete confidence.

- Mid-program restart allows the operator to start anywhere in a program by verifying the graphics and then switching to Run Mode - no need for G- and M-code expertise.

- The Series 9000 features an Intel Dual Core i5 64 bit processor and high-speed motion control that can execute up to 3,000 blocks per second so customers can run their most demanding programs in the shortest time. The Series 9000 control offers 4 GB memory, 120 GB solid state disk storage and two USB ports.

Milltronics utilizes a complex "Feed Forward" error correction algorithm that reduces inaccuracy caused by corner rounding and following error without compromising speed as well as true S curve acceleration and jerk correction - essential ingredients for high speed machining.

An optional feature for the Series 9000 is Milltronics Shop View (MSV), which allows users to access machine status and collect usage and diagnostic info per Industry 4.0. MSV is hosted in the cloud and can be accessed with a PC, tablet or smartphone.

Additional key specifications include:

- Number of cores: 2

- Processor base frequency: 2.7 GHz

- Max turbo frequency: 3.3 GHz

- GPU core speed: 600 MHz

- Primary OS: Windows Embedded 7

- Display: 15" color 1024 x 768 touchscreen.

For more information contact:

Bill Bender

Milltronics USA, Inc.

1400 Mill Lane

Waconia, MN 55387

952-442-1410

bbender@milltronics.com

www.milltronics.com

SOUTHWEST

OK

Hillary Machinery LLC

877-741-4392

jeff@hillaryllc.com

www.hillaryllc.com

AR

TECHMACH

479-636-1884

sales@techmach.net

www.techmach.net

LA

Cardinal Machinery

901-377-3107

info@cardinalmachinery.com

www.cardinalmachinery.com

NM

Milltronics USA Direct

888-999-1440

sales@milltronics.com

www.milltronics.com

TX

Hillary Machinery, Inc.

972-578-1515

sales@hillaryinc.com

www.hillaryinc.com

SOUTHEAST

AL, MS, TN

Cardinal Machinery

901-377-3107

info@cardinalmachinery.com

www.cardinalmachinery.com

FL

APT Machine Tools

321-280-2481

machinesalesapt@aptmtools.com

www.aptmtools.com

NC, SC, GA

Machinery Solutions

803-359-7000

sales@machinerysolutions.com

www.machinerysolutions.com

VA

Production Machinery

757-258-5800

drd@productionmachinery.net

www.productionmachinery.net

NORTHEAST

NY

Precision Technologies

585-389-1065

sales@precisiontechnologies.us

www.precisiontechnologies.us

CT, ME, MA, NH, RI, VT

ABLE Machine Tool Sales

413-786-4662

sales@ablemts.com

www.ablemts.com

E. PA, MD, DE

Precision Machine Tool Solutions

610-670-6780

sales@pmtscnc.com

www.pmtscnc.com

W. PA

Allegheny Machine Tool Systems

800-269-4090

www.allegmach.com

NJ, S.W. NY

21st Century Machine Tools

973-808-2220

kim@21stCmt.com

www.21stCmt.com

WV

Mabscott Supply Co.

800-642-5160

mike@mabscottsupply.com

www.mabscottsupply.com

MIDWEST

N. IL

520 Machinery Sales

888-520-1768

sales@520machinery.com

www.520machinery.com

S. IL, E. MO

TECHMACH

479-636-1884

sales@techmach.net

www.techmach.net

MI, N. IN

KM Industrial

269-381-0690

kmim@kmim.net

www.km-industrial.com

OH, S. IN, N. KY

Advanced Machinery

800-759-7337

cnc@advancedmachinery.com

www.advancedmachinery.com

IA

Greenway & Associates

712-737-8700

sales@greenwayaassoc.com

www.greenwayassoc.com

KS, W. MO

Kansas Oklahoma Machine Tools

(KOMT)

316-945-6800

wichita@komt.com

www.komt.com

S. KY

Cardinal Machinery

901-377-3107

info@cardinalmachinery.com

www.cardinalmachinery.com

MN, ND, SD

Concept Machine Tool

763-559-1975

sales@conceptmachine.com

www.conceptmachine.com

WI

Concept Machine Tool

262-646-4488

sales@conceptmachine.com

www.conceptmachine.com

NE

Industrial Systems and Supply

402-564-4445

info@industrial-systems-supply.com

www.industrial-systems-supply.com

WEST

AZ

White's Niche Products, LLC

602-290-9402

wnp@earthlink.net

www.wnpllc.com

ID, MT, N.CA, NV, N.W., OR, UT, WY, WA

Milltronics USA, Direct

888-999-1440

sales@milltronics.com

www.milltronics.com

S. CA

SoCal Machine Tools

562-986-9999

rene@socal-machinetools.com

www.socal-machinetools.com

CO

Advanced Industrial Technology

800-321-3195

hanko@aittools.com

www.aittools.com