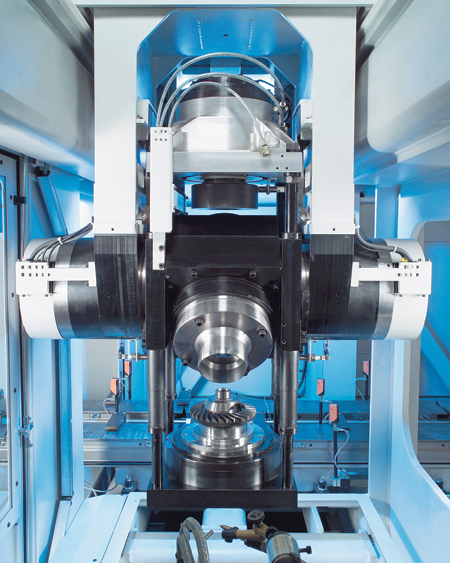

The ELC 250 DUO is a compact laser machining center for machining differential housings. The duo version of the ELC has twin spindles. This two-station mode allows the working spindles to be loaded and unloaded during the machining time.

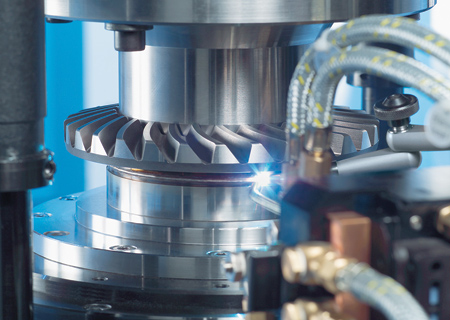

Laser welding the differential gearbox housing and the ring gear has allowed the component weight to be reduced by around 1.2 kg.

The ELC 250 DUO is fitted with two swiveling pick-up spindles.

Laser welding a ring gear to a differential housing.

"Whether hybrids, fully electric vehicles or power units with fuel cells, the future of mobility is far from clear and remains exciting," said an EMAG spokesperson. "The one thing that is certain, however, is that changes will come for which the industry will have to find flexible solutions.

"In addition these new, big ideas, many small changes are taking place that also have a major influence on the success of new products. Classic components, such as differential gearboxes, will continue to be manufactured in the future, regardless of the type of energy that powers the vehicle. EMAG provides manufacturing solutions for the entire differential gearbox - with the particular highlight being laser welding systems for differential housings and ring gears based on the EMAG ELC 250 Duo Laser Cell."

When discussing optimizing the production of gearbox components, there are two main aspects to speak of: optimizing the component itself, for example in terms of quality and weight; and improving the production process to reduce component costs. "With regard to laser welding technology in general, and the ELC 250 DUO laser welding machine in particular, major benefits can be generated in both areas," said the spokesperson.

The Challenge: Connecting the Ring Gear and Differential Housing

"There are two unbeatable arguments in favor of substituting the classic screw connection between a ring gear and differential housing that are sure to capture the attention of any manufacturer of axle transmissions: reducing weight and cost," said the spokesperson. "The weight saving for a welded differential in a car engine is around 0.6 to 1.2 kg, a clear cost savings considering the reduced material consumption, the elimination of machining and the assembly for the high-strength screws required."

There are special requirements to take into consideration. First of all, a range of different materials is used. While the differential housing is made of a cast material, the ring gear is made of case hardened steel. As a result of the material hardness, welding cast is a critical process and it is essential it be tailored to the specific component. There are no off-the-rack solutions.

Another challenge is the pre-assembly of the differential gearbox housing. Contamination from previous production processes (oil, assembly pastes, etc.) can adversely affect the welding process, resulting in cracks in the weld. Cleaning the welding zone is therefore crucial, also for the ring gear generally surface treated by phosphating that can also adversely affect the welding process and must be cleaned.

The ELC 250 DUO

EMAG Automation has already supplied more than 20 complete systems for the joining and laser welding of differential gearboxes - each of them tailored to the customer and their level of automation, flexibility, layout and process. The heart of every system is the ELC 250 DUO laser welding machine, also developed and manufactured by EMAG Automation. The ELC 250 DUO has two machining areas. The twin-spindle design is consistent with the goal of the entire system to achieve maximum productivity. To this end, the ELC 250 DUO uses the typical EMAG pick-up principle of self-loading working spindles.

There are several benefits to using pick-up spindles. This principle allows fixed lenses to be used since the workpiece moves rather than the tool, and it allows loading and unloading to take place during the cycle time so as to reduce idle times. The benefits resulting from the fixed lenses cannot be underestimated in terms of safety. The fact that the lenses are fixed means that the laser is always directed into the inside of the machine, guaranteeing an excellent level of protection for the user. Furthermore, fixed lenses ensure process reliability since all the laser technology and logistics for operating the laser must only be set up once and do not need to be changed again.

Operational Safety and Ease of Servicing

The optical system is simple yet robust. "Using its expertise in machine tool manufacturing, EMAG has created a high precision, heavy-duty production solution. This provides the perfect platform for reliable large series production," said the spokesperson. The optimized beam control and targeted extraction protect the lenses from contamination during the welding process.

The ELC 250 DUO can be equipped with the latest laser technology to suit component requirements and the customer's specifications. Although the process takes place on two stations within the ELC 250 DUO, only one laser source is required. A beam deflector is used to switch the laser between the focusing lenses at the two welding stations. This improves the usage of the laser and increases the productivity of the laser welding system.

In addition to high precision, the machine offers high flexibility of equipment (additional sensors, brushes, tests, etc.).

EMAG Industrial Standard

Process development is an integral part of EMAG's services. Every workpiece is different and every customer has different requirements. "We are proud that our production concept has defined the industrial standard for the manufacture of gears using production laser welding," said Peter Loetzner, President and CEO of EMAG L.L.C. "EMAG is not just a builder of the very latest laser welding machines; primarily we are a developer of complete manufacturing systems, which have made us very successful in the market for many years."

EMAG delivers custom manufacturing solutions for the laser beam welding of components for powertrain, steering shafts, camshafts and other vehicle components. The company regards itself as a turn-key supplier that not only deals with the welding process and laser welding machine, but also integrates the automation system with parts logistics, clamping devices, part cleaning systems and even the company's own ultrasound testing equipment for its manufacturing systems, and thus continues to drive forward the use of laser technology in the automotive industry.

Benefits of laser welding include:

High power density

High process speed

Low heat stress and therefore low component warpage

High process reliability

Use of the latest solid-state lasers.

For more information contact:

Kirk Stewart

Sales Director

EMAG L.L.C.

38800 Grand River Ave.

Farmington Hills, MI 48335

248-966-4703

kstewart@emag.com

www.emag.com

SOUTHWEST

TX, OK, LA, AR

Ric Lorilla

Regional Sales Manager

EMAG L.L.C.

248-595-1530

rlorilla@emag.com

SOUTHEAST

MS

Ric Lorilla

Regional Sales Manager

EMAG L.L.C.

248-595-1530

rlorilla@emag.com

VA, NC, SC, FL, GA, AL

Dave Fitzgerald

Regional Sales Manager

EMAG L.L.C.

248-595-1117

dfitzgerald@emag.com

TN

Mark Comeaux

Regional Sales Manager

EMAG L.L.C.

248-938-2097

mcomeaux@emag.com

NORTHEAST

WV

Dave Fitzgerald

Regional Sales Manager

EMAG L.L.C.

248-595-1117

dfitzgerald@emag.com

ME, NH, NY, PA, MA, RI, CT, NJ, DE, MD, VT

Troy Martz

Regional Sales Manager

EMAG L.L.C.

248-938-2430

tmartz@emag.com

MIDWEST

OH, KY

Mark Comeaux

Regional Sales Manager

EMAG L.L.C.

248-938-2097

mcomeaux@emag.com

ND, SD, NE, KS, MN, IA, MO

Bill Konetski

Regional Sales Manager

EMAG L.L.C.

612-804-0857

bkonetski@emag.com

IL, IN

Tod Petrik

Regional Sales Manager

EMAG L.L.C.

248-470-2646

tpetrik@emag.com

WI, MI

Joe Thompson

Regional Sales Manager

EMAG L.L.C.

248-880-0233

jthompson@emag.com

WEST (none, use HQ)