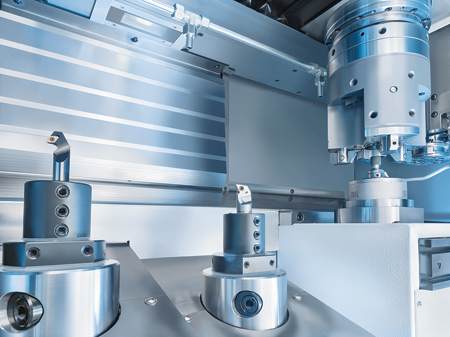

Combination hard turning and grinding on the VLC 100 GT

Turning and grinding: complete-machining on a VLC 100 GT

Hard turning on the VLC 100 GT

With integrated O-automation for workpiece transport, the VLC 100 CT is loaded and unloaded using the pick-up principle. Also shown is the measuring probe.

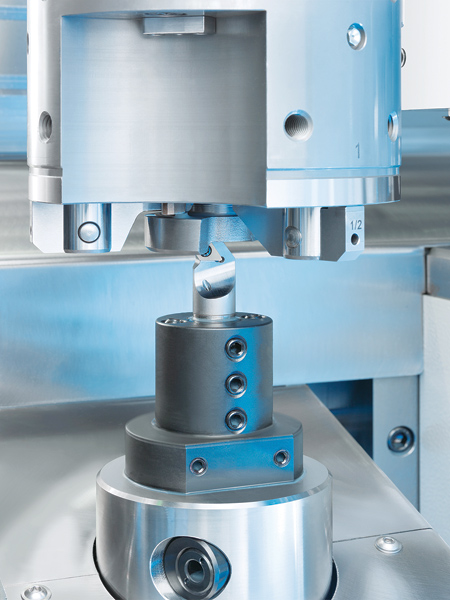

Internal grinding of a bore on the VLC 100 GT

The integrated measuring probe is used to check the machining quality at programmed intervals.

When it comes to machining times, combining various machining processes in one set-up offers enormous savings potential. With the combination of hard turning and grinding, for example, only the geometries that require greater precision are ground after turning. For this requirement, EMAG developed the VLC 100 GT that efficiently combines vertical turning technology with finish grinding. "For chucked components up to 100 mm in diameter, such as gears, single cams and cam rings, pump rings or sprockets, first-grade machining results are achieved with massively reduced cycle times," said a company spokesperson.

The VLC 100 GT integrates combination machining into EMAG's pick-up concept, where the main spindle is used to load and unload workpieces from the integrated conveyor belt or shuttle. The machining area is easy to equip with a variety of turning and grinding modules. This compact manufacturing system also includes integrated measuring.

Two machining processes that lend themselves for ideal combination are turning/hard turning and grinding. The first step is to pre- or complete-machine all of the component surfaces that can be hard turned, and then, without having to change the set-up, finish grind all areas that require high-precision geometries. "This process has two advantages: the turning process is considerably faster than grinding flat surfaces, and wear and tear on the grinding tools is vastly reduced with only finish grinding operations carried out," said the spokesperson. "Since the workpiece is machined in a single set-up, the whole process is more efficient than when carried out on two machines. It also results in reduced component costs and guarantees the same, if not better, component quality."

The customer benefits from the flexible configurability of the VLC 100 GT, since it covers a wide range of applications. For example, it can be used as a conventional vertical grinding center equipped with two grinding spindles for external and internal grinding, or for combination machining, with an additional block toolholder for hard turning operations. The VLC 100 GT can be equipped with corundum or modern CBN grinding technology and vitrified-bonded CBN grinding wheels can be dressed using a rotating diamond roll. A structure-borne sound system serves as GAP control between the dressing roll and grinding wheel. An adaptive process control system achieves the shortest possible cycle times.

"All vertical pick-up machines from EMAG feature a machine base made of MINERALIT polymer concrete that stands out for its damping effect, eight-times greater than a cast iron base," said the spokesperson. "This exceptional vibration damping quality significantly contributes to the excellent surface finish of the components. Optimal machining quality is achieved with the integrated measuring probe, located between the machining area and pick-up station, where it is not only protected from debris, but allows the measuring process to take place in the same set-up, either directly before or after machining to save clamping time." The probe can also be used to take intermediate measurements.

One example where the VLC 100 GT displays the advantages of combination machining is in the machining of sprockets. Once the pick-up spindle has loaded the component, the integral internal grinding spindle performs the first operation. Then the sprocket bore, with its small allowance, is finish ground with CBN. The two block toolholders, present in the machining area, then machine the flat surfaces on the sprocket. The hard turning technology used for this operation not only results in short machining times, but it also ensures that no subsequent operations are necessary. The measuring probe, located between the machining area and the loading station, will now check the machining quality. The whole process takes under 50 seconds and is performed in one clamping operation.

With the VLC 100 GT, EMAG has created a system for the combination machining of chucked components. "Making use of the pick-up spindle to load the machine, plus the application of enhanced grinding technologies in combination with turning operations, provide a machine design firmly focused on performance - as the above example shows," said the spokesperson. "Whether the VLC 100 GT is used in a production line for the manufacture of large quantities of components or as a stand-alone, this vertical turning/grinding center offers itself to a vast range of applications."

Technical data for the VLC 100 GT:

- Chuck diameter, max.: 160 mm

- Machining diameter, max.: 100 mm

- Main spindle - power rating at 40/100% duty cycle: 19.5/12.5 kW

- Swing diameter: 210 mm

- Travel in Z: 375 mm

- Travel in X: 900 mm

- Main spindle speed, max.: 6,000 RPM

- Main spindle - torque at 40/100% duty cycle: 75/48 Nm

- Main spindle - front main spindle bearing, max. diameter: 80 mm.

For more information contact:

Kirk Stewart

Sales Director

EMAG L.L.C.

38800 Grand River Ave.

Farmington Hills, MI 48335

248-966-4703

kstewart@emag.com

www.emag.com

SOUTHWEST

TX, OK, LA

Ric Lorilla

Regional Sales Manager

EMAG L.L.C.

248-595-1530

rlorilla@emag.com

AR

Steve Cox

Regional Sales Manager

EMAG L.L.C.

248-752-2298

scox@emag.com

SOUTHEAST

VA, NC, SC, E. FL, E. GA

Dave Fitzgerald

Regional Sales Manager

EMAG L.L.C.

248-595-1117

dfitzgerald@emag.com

MS, TN, AL, W. GA, W. FL

Steve Cox

Regional Sales Manager

EMAG L.L.C.

248-752-2298

scox@emag.com

NORTHEAST

WV

Dave Fitzgerald

Regional Sales Manager

EMAG L.L.C.

248-595-1117

dfitzgerald@emag.com

ME, NH, NY, PA, MA, RI, CT, NJ, DE, MD, VT

Troy Martz

Regional Sales Manager

EMAG L.L.C.

248-938-2430

tmartz@emag.com

MIDWEST

S. IN, OH, KY

Mark Comeaux

Regional Sales Manager

EMAG L.L.C.

248-938-2097

mcomeaux@emag.com

ND, SD, NE, KS, MN, IA, MO

Bill Konetski

Regional Sales Manager

EMAG L.L.C.

612-804-0857

bkonetski@emag.com

IL, N. IN

Tod Petrik

Regional Sales Manager

EMAG L.L.C.

248-470-2646

tpetrik@emag.com

WI, Chicago

Joe Thompson

Regional Sales Manager

EMAG L.L.C.

248-880-0233

jthompson@emag.com

MI

Mark Ashworth

Key Account Manager

EMAG L.L.C.

248-826-4242

mashworth@emag.com

WEST (none, use HQ)