The operation of this MJC rotary forging press involves the application of pressure on a small portion of material at a time, reducing stress and saving up to 90% in material, compared to subtractive machining from a solid blank.

Siemens CNC controls the entire machine process

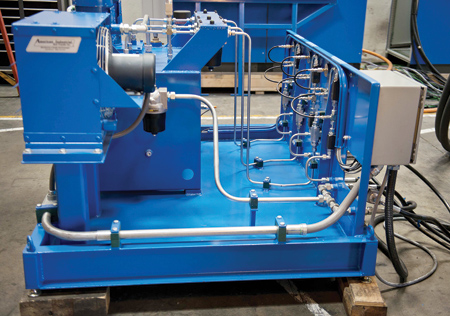

Lubrication manifold

Hydraulic manifold

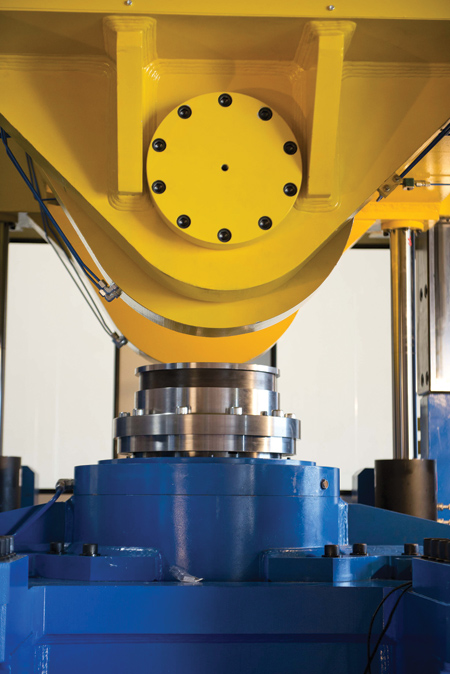

Bottom spindle holds the workpiece in position

Operator loads workpiece during test run-up on machine; very hard aerospace materials such as Hastelloy and Inconel are typically processed

Twin rotating spindles cold form the metal under pressure

New rotary forge press from MJC, built specially for the Advanced Forming Research Centre (AFRC) at the University of Strathclyde in Scotland. Two independent and synchronized rotary dies are fully programmable on the Siemens CNC to affect 0 - 45° pitch angles.

AFRC facility performs fundamental and applied research on the forming and forging of metals, primarily for aerospace applications. A full battery of materials and performance testing is conducted at AFRC by a team of materials and process experts.

MJC Engineering is a custom machine tool builder, specializing in metalforming machines for such applications as spinning, flow forming, wheel spinning and rotary forging. The company was recently contracted by the Advanced Forming Research Centre (AFRC) at the University of Strathclyde in Glasgow, Scotland, for a very unique application. The application is a cold-forming rotary forge press that works the material between two synchronized rotary dies. The dies operate in an angle from the parallel. Typically, the angle is fixed but, on this custom designed machine from MJC, the angle is fully programmable. This configuration allows compression in a concentrated area and provides a more efficient method for metal deformation, while producing superior mechanical properties in the finished section. "Up to 90 percent material savings can be achieved by the use of this revolutionary metalforming technology, in comparison to conventional machining from a solid blank," said a company spokesperson.

The aim of this new CNC technology, according to MJC President Carl Lorentzen, is to make the aerospace engineers rethink how they design products, so that a maximum material savings on exotic and costly metals can be realized.

Rotary forging can be defined as a two-die forging process that deforms only a small portion of the workpiece at a time, in a continuous manner. The reduced instantaneous area of tool and workpiece contact means lower forging forces are required to cause deformation in the material. Typical components for rotary forge operations are round or cylindrical hollow parts that deploy expensive or exotic alloys, require extreme material property targets or involve very complex geometries. At AFRC, the rotary forging machine provided by MJC is processing AerMet 100, Inconel 718 and Allvac 718Plus, Ti-6Al-4V as well as the creep-resistant Ti6242 and some beta alloys.

Onboard the machine, the bottom and top spindles pivot from 0 - 45°, operated by AC vector motors and drives, plus an overall motion control CNC, all provided by longtime supplier to the builder, Siemens. The CNC is a Sinumerik 840D, which controls all the axis and spindle motion, hydro and servo positioning valves, plus the synchronization of up to four cylinders for the integrated motion of the rotary dies. In the processing of the workpiece, the control is monitoring all machine conditions, while maintaining the synchronized angles of the twin rotary dies.

Programmed motion sequences on the machine must be maintained with high precision to avoid improper deformation of the materials during the cold-forming process. "In a manufacturing environment, where the high production output of parts is critical, this process must remain extremely well-regulated, documented and monitored. The CNC has the capability to upload all data in real time," said a company spokesperson.

"Though the concept of the rotary die forge is certainly not new, the computer-controlled synchronized dual rotary dies on this machine offer a number of unique advantages in the cold-forming process of metals," said Lorentzen. "The idea originated in a somewhat different form in the automotive market with the development of a front wheel hub hollow shaft. The cold-forming of metal around a bearing was combined with robot loading in production. The concept, combined with the Siemens CNC and its ability to control all the motion so precisely, made the development of this machine more practical for us."

MJC is a custom machine tool builder, with equipment currently serving in the military, aerospace, general metalforming and automotive after-market segments of industry. The company is a member of PMA, NFTC and AMT.

The AFRC is jointly sponsored by the Scottish government, Scottish Enterprise and a variety of international aerospace manufacturers and engineering firms, including Boeing, Rolls Royce, TIMET, Aubert & Duval and Barnes Aerospace. It has operated as a world-class facility, supporting fundamental and applied research into the forming and forging of metals, since 2009. Having doubled in size recently, AFRC is expanding its market applications into the automotive, energy and marine markets. The center can currently heat, shape, finish, measure, test and analyze all types of metal materials and components in-house. The research done here comprises investigations into residual stress, die life, process characterization, materials characterization, heating and thermal processes, super-plastic forming, sheet forming and related technologies in automation, metallurgy and metrology.

For a video link to see this machine in action go to: https://youtu.be/muknV6jBiZg.

For more information contact:

Carl Lorentzen, President

clorentzen@mjcengineering.com

Per Carlson, VP

carlson@mjcengineering.com

MJC Engineering & Technology, Inc.

15701 Container Lane

Huntington Beach, CA 92649

714-890-0618

www.mjcengineering.com

John Meyer

Siemens Industry, Inc.

Drive Technologies - Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

847-640-1595

siemensmtbumarcom.sea@siemens.com

www.usa.siemens.com/cnc