The expansion of CELOS as an integrative platform of digitalization is a core feature for DMG MORI. The aim is capability of a cloud-based interaction from controlling production to planning the business.

CELOS is designed for smooth entry into the future of metalcutting production, because this takes place gradually. Customers who choose CELOS today receive unlimited access to the existing 16 CELOS apps and then will benefit from future applications.

With the use of CELOS apps and DMG MORI Technology Cycles customers can benefit from digital machining solutions based on unique local intelligence.

The topic of Industry 4.0 is dominating the discussion of the future in the sector of machine tool construction. DMG MORI supports its customers on their way to digital transformation with the app-based CELOS system and other intelligent software solutions.

CELOS from DMG MORI

A key building block in DMG MORI's customer-oriented digitalization strategy is the app-based CELOS system, which the machine tool manufacturer first presented around three years ago and which it has continued to develop ever since. Using this uniform user interface for machine and office PC, employees in shop floor and job scheduling can manage, document and visualize job order, process and machine data.

Due to its open architecture, CELOS allows the exchange of information with higher-level structures in addition to its effects on the shop floor.

CELOS offers entry into software products related to Industry 4.0. Customers who choose CELOS today receive unlimited access to the existing 16 CELOS apps and then benefit from future applications.

The CONTROL app from CELOS enables the continued use of existing programs, so employees can continue to work in their familiar programming and control environments.

DMG MORI Process Chain

The DMG MORI process chain is an example of a digital transformation and a practical link from the virtual to the real world. This is demonstrated by the partnership between DECKEL MAHO Seebach GmbH and the Porsche Motorsport Team. Porsche has won the drivers' as well as the manufacturers' classification in the recently finished season of the World Endurance Championship.

The Porsche Motorsport Center in Seebach produces among other things complex pump housings from different materials and technically demanding fixing elements in mini-series. The developers from the racing team supply the necessary CAD data, while the machining experts in Seebach are responsible for the entire process through to the finished workpiece. It starts with the processing of the CAD data and CAM programming with the Siemens NX CAM and on to 1:1 simulation on the DMG MORI Virtual Machine and right on through to the high-precision finishing on DMG MORI high-tech machines.

Based on the virtualized process chain, machining centers can be optimized in advance, thus allowing perfect planning, effective prevention of collisions and a reduction of set-up time.

Technology Cycles from DMG MORI

Workshop-oriented programming is still of great importance especially in single item production and the production of small and medium-sized quantities - and it will remain just as important for a long time to come. Whereby working with cycles is now state-of-the-art and standard cycles for turning, milling and drilling have long been included in the performance range of modern controls.

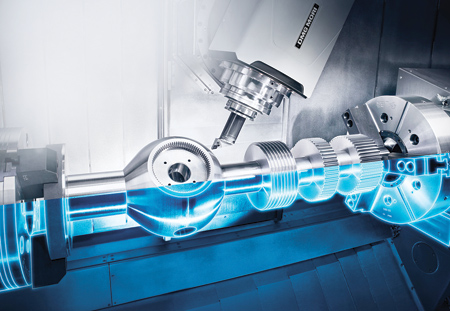

DMG MORI currently has 24 exclusive DMG MORI Technology Cycles for the fields of turning / turning-milling or milling / milling-turning in its portfolio. These enable the operator in the workshop to program complex machining directly on the machine via a dialog using parameterized context menus.

Examples include the machining of free-form surfaces using 5-axis interpolation or various cycles for gear cutting or gearwheel production. Other cycle highlights include the Machine Protection Control for the protection of machines, workpiece and tool, the 3-D quickSET toolkit for checking and correcting the kinematic accuracy of 4- and 5-axis machines or the Application Tuning Cycle for the process-oriented tuning of feed drives at the push of a button in relation to the table load.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline: 855-DMG-MORI (364-6674)

www.us.dmgmori.com