Methods to Host TechFest2015 November 4–5

November 4, 2015Methods Machine Tools, Inc. will be hosting TechFest2015, "Manufacturing the Future," an open house event that will take place November 4-5, 2015 from 9:00 AM - 5:00 PM each day at the company's corporate showroom and technology center at 71 Union Avenue in Sudbury, MA.

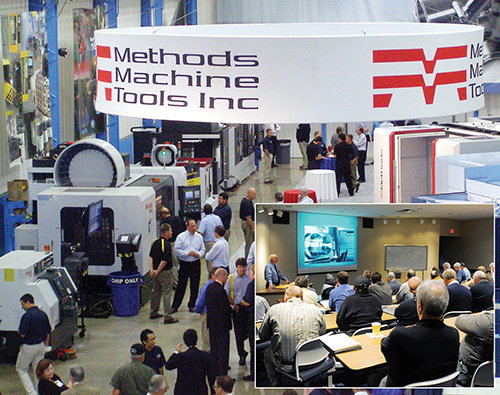

Over 30 machines will be under power and multiple technical seminars will be featured at TechFest2015 "Manufacturing the Future" event.

TechFest2015 will feature the latest machine tool technology and automation – over 30 machines under power with live demonstrations and multiple automation and turn-key projects. The two-day event will also feature Reshoring expert Harry Moser as keynote speaker as well as a seminar on the future of metal additive manufacturing. In addition, attendees can participate in technical seminars and discuss applications with Methods' engineers. This year Methods will showcase eight partners / manufacturers at TechFest2015 including:

• YASDA precision machining centers

• KIWA horizontal machining centers

• Nakamura Tome multitasking / turning centers

• FEELER high performance milling and turning centers

• FANUC EDM and drill / tap centers

• Current EDM drilling solutions

• VisionGauge digital optical comparators

• Hanwha Swiss turning machines

TechFest2015 Technical Seminars Presented on Both Days

• The Reshoring Initiative, presented by Keynote Speaker Harry Moser.

• The Future of Metal Additive Manufacturing: Methods 3-D, presented by Ben Fisk, Methods

• How Small Shops Break into Automation, presented by John Lucier, Methods.

• Unleash the Power of FANUC's Wire EDM, presented by Steve Bond, Methods.

• The R.O.I. of Tool Pre-setting, presented by Andrew Esposito, Koma Precision.

• Simple Approach to Twin Spindle Technology, presented by Rich Parenteau and Ken Corklin, Methods.

• Introduction to Zeiss PI-Web, presented by Tom Wojtoviets, Zeiss.

• Geometric Dimensioning and Tolerance (GD&T) in the Manufacturing World Today, presented by Mark Foster, President of Applied Geometrics, Inc.

• VisionGauge Comparative Solutions, presented by Patrick Beauchemin, President of VisionX. "We are excited to offer this event to manufacturers who are looking to experience the latest technology via leading-edge precision machine tools and automation solutions,” said Bryon Deysher, President & CEO, Methods Machine Tools, Inc. "This is an ideal time for our customers and prospects to speak with our applications experts and discuss their company's unique needs."

TechFest2015 Machines to be Displayed

• YASDA, featuring the PX-30i, a 5-axis machining center with multiple pallets, increased tool capacity with matrix style changer, advanced tool and pallet management system. Also featuring the H40i, a machine designed to meet the demands for tighter tolerances and shorter cycle times required by manufacturers in segments such as aerospace, die/mold and automotive, as well as the YBM 640v, a 3-axis CNC vertical jig borer which is engineered for high speed, precision boring and milling operations for high accuracy mold, die and complex component manufacturing.

• Nakamura-Tome, featuring the NTRX-300, the latest B-axis tool spindle; a heavy-duty machine with full twin spindles and a robust tool spindle, said a spokesperson. In addition, Nakamura-Tome will showcase the AS-200LMY-S, sub-spindle machine, a multitasking turning center designed for value and power. The new AS-200LMY-S offers an upgraded long bed with sub-spindle. "The NTMX is the world's first twin ATC B-axis lathe, featuring the new Smart X control from Nakamura using Windows 8 software," said the spokesperson. And the TW20-MMY designed for fast and flexible machining with twin-spindle and twin-turrets, will also be displayed.

• KIWA, featuring a KMH-300 HMC that includes a 30-tool ATC and 15,000 RPM BT30-taper spindle. The KMH-630, which offers an integrated full rotary B-axis and a FANUC Oi-MD control with a 15 in. LCD screen will also be on display. Also on display will be the KH-45 Series, which now include models with more Y-axis travel to 29” (737 mm), to enable tall parts that would normally require a 500 mm size machine, to be processed on a smaller footprint machine.

• FANUC, showcasing the FANUC RoboCut C400iA, which offers a solid performance in a smaller footprint and stated Methods, the RoboCut C600iA, which represents the best value in class for Wire EDMs. These EDM machines include several important upgrades including the new FANUC 31i-WB control, which is loaded with new features for improved accuracy and finish, especially in high-taper 4-axis cutting.

The RoboDrill a-D21LiA5-10K long bed, will also be on-hand and is the largest version in the FANUC RoboDrill lineup. In addition, a RoboDrill a-D21MiA5-24K medium bed, featuring a Koma 5-axis RTT-111CA rotary table with Erowa quick-change chuck, Blum laser, high pressure coolant system and MistBuster will be on display; and a RoboDrill a-D21MiA-10K medium bed, designed for high performance and a compact machine center based around reliability and speed, said Methods. "The RoboDrill a-D21SiA-10K short bed, a compact vertical machining center capable of high speed, high precision and efficient operation will round out the FANUC machines on display," said the spokesperson.

• FEELER, displaying the FT-350 MC, a 3-axis CNC mill-turn lathe, including the HV-1300, a high performance vertical machining center with 30-tool dual swing arm ATC and FANUC 31i-MB control. Additional machines will be the FTC-100 turning center with slant bed / boxway construction and a FANUC 0i-TC control; and the FEELER VMP-580, available in both regular and APC models, featuring linear guideways on X, Y, and Z-axes, a 6-second pallet change time, and a 15,000 RPM BIG-Plus 40 taper spindle.

• Hanwha XE-20, showcasing an affordable Swiss type turning center with a gear type modular live tool, designed for enhanced durability and strong/ rigid tool post.

• VisionGauge, displaying the 300 and 500 Series digital optical comparators with patented CAD Auto-Align and CAD-Auto Pass/Fail tools, as well as the new 700 series that features a 5-axis inspection and measurement system.

• Current EDM, featuring the CT500, a medium capacity CNC EDM drilling machine specifically designed for production drilling of complex parts that require multi-axis positioning.

• Zeiss, showcasing multiple CMM models in a dedicated showroom.

Methods Machine Tools invites all manufacturing professionals to attend TechFest2015 to see the extensive range of machining and automation solutions the company offers. For more information or to register for TechFest2015, please visit www.methodsmachine.com/techfest2015 or call 978-443-5388.

For more information contact:

Methods Machine Tools, Inc.

65 Union Avenue

Sudbury, MA 01776

978-443-5388

sales@methodsmachine.com

www.methodsmachine.com

www.methodsmachine.com/techfest2015

< back