Compact design: The enclosure also contains the electrical cabinet and the energy container. Equipping the machine with an automatic loading system is an option.

Access to the PMD 2 crankshaft grinder components is easy.

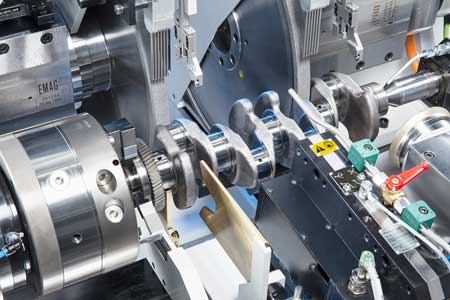

Two grinding wheels are used for the simultaneous machining of two pin bearings, reducing cycle time considerably.

Prospects for the international automotive industry are promising, with expected growth in the coming years supported by growing demand in the Asian markets. Competition continues to increase, especially from Asian companies. In addition, more rigorous national emission limits and safety requirements lead to an increase in production costs, causing planners to review their manufacturing technologies for potential savings. In the example of the crankshaft, which the engine depends on for efficiency and stability, a work-intensive grinding operation in the micrometer range is required.

EMAG has developed a tailor-made grinding solution for shaft-type components. The new PMD 2 machine is designed for the machining of passenger car crankshafts and features twin grinding heads that allow the simultaneous grinding of two pin or main bearings in a single set-up using two grinding wheels. Its capacity covers small components up to 500 mm length. "With this machine we are rounding out our range of crankshaft grinders to include the machining of smaller components," said Dr. Guido Hegener, Managing Director of EMAG Maschinenfabrik GmbH. "Up to now, our range of machines did not include a horizontal twin-head grinder for smaller crankshafts. This gap is now filled with the PMD 2."

The basis for the PMD 2 is the established "Series 2" from EMAG NAXOS-UNION and EMAG KOPP. "These machines combine high-tech grinding technology with precision, great efficiency, process integrity and simple operation," said the spokesperson. "This applies to the PMD 2 as well, where two CBN grinding wheels machine crankshafts to the highest precision."

To achieve this, the machine is equipped with a direct-driven workspindle, hydrostatic guideways and a linear motor in the X-axis, as well as an in-process measuring control that allows for roundness monitoring and correction in the machine. "The operator enters the relevant command in the control and the measuring process is carried out once the bearing has been ground. The software, developed by EMAG, then calculates the relevant correction values from the remaining roundness errors. This allows for the subsequent manufacturing processes to be successively optimized," said Hegener.

The technology also uses two grinding wheels. The twin-tool process opens up a number of possibilities for the user, depending on component and machining requirements. Two pin bearings or main and pin bearing are machined simultaneously, reducing cycle times. For instance, a four-cylinder crankshaft is machined in less than two minutes. The grinding wheels can, if required, be arranged very close together so that adjoining pin and main bearings can be machined simultaneously. Both grinding spindles and work headstock are direct-driven.

The machine also features a compact but flexible construction, for example the electrical cabinet is included in the enclosure. Connecting an automatic loading system poses no problem, and both emulsion and oil can be used as coolants. "Flexibility was of great importance in using this technology," said Hegener. "We tailor the machine exactly to the customer's requirements. Integration into an existing, complex production line is an important option, but there is the option of the machine being used as a stand-alone solution with manual loading. We expect this approach will give users a competitive edge while component quality and production costs are gaining importance world-wide."

For more information contact:

Peter Loetzner

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

248-477-7440

info@usa.emag.com

www.emag.com

Southwest

AR

David Fitzgerald

EMAG LLC

248-595-1117

www.emag.com

TX, OK, LA

Ric Lorilla

EMAG LLC

248-595-1530

rlorilla@emag.com

Southeast

VA, NC, SC, GA, FL, TN, AL, MS

David Fitzgerald

EMAG LLC

248-595-1117

www.emag.com

Northeast

PA, NY

Kirk Stewart

EMAG LLC

248-996-4703

kstewart@emag.com

ME, NH, VT, MA, RI, CT, NJ, DE, MD

Jonathan Chomicz

EMAG LLC

248-497-8526

jchomicz@emag.com

WV

David Fitzgerald

EMAG LLC

248-595-1117

www.emag.com

Midwest

IN, MI, OH

Kirk Stewart

EMAG LLC

248-996-4703

kstewart@emag.com

ND, MN, WI, SD, NE, KS, IA, MO, IL

Tod Petrik

EMAG LLC

248-470-2646

tpetrik@emag.com

KY

David Fitzgerald

EMAG LLC

248-595-1117

www.emag.com

West

Peter Loetzner

248-477-7440

info@usa.emag.com

Arnie Sugiyama

Caltec International

19801 Hamilton Ave

Torrance, CA 90502

310-527-4110

arnie@caltecusa.com