COORD3 Metrology BENCHMARK CMM.

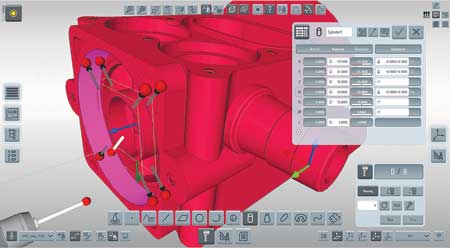

Rich screen graphics of the TouchDMIS software display every action before execution, guiding the measuring process and eliminating potential user errors.

The BENCHMARK CMM from COORD3 is designed to be a high performance budget CMM with the added benefit of a small footprint. The half-gantry alloy design has its X and Y axes at the same level, providing increased rigidity and an enhanced metrology platform for high accuracy small and medium part CMM inspection, according to the company.

"The open structure BENCHMARK provides better ergonomics and is ideal for the inspection of high volume production parts or single part inspection in smaller manufacturing operations," said a company spokesperson. "Its compact size is ideal for production CMM or quality room applications and fits through a standard door width."

The full air-bearing BENCHMARK CMM, with accuracy of 2.5 microns and a measuring volume of 500 mm x 400 mm x 440 mm, comes standard with a Renishaw touch probe.

BENCHMARK is available in manual or CNC configurations. Manual units can be upgraded to full CNC in the field at a later date, offering a two-phase investment in CMM technology. The CMM can be used for the job shop and can also be used as a programmable production gage. Optional wireless thermal compensation is designed to allow the BENCHMARK to measure accurately in shop conditions.

"This BENCHMARK CMM is equipped with TouchDMIS, offering all touch CMM software with full CAD capability," said the spokesperson. "TouchDMIS requires just a few hours of training and features a short learning curve.

"The software's Measurement Wizard and Construction Professor minimize user input to the software; access to the DMIS programming language is not required for measurements, programming or editing. TouchDMIS is loaded with innovative time saving features. Built in intellect provides the user with screen dynamics minimizing selection choices and eliminating traditional function searches. Rich screen graphics display every action before execution guiding the measuring process and eliminating potential user errors. Measured data can be presented as a unique Blueprint Report whereby a fully dimensioned drawing of the measured part is created for fast and easy interpretation of measured results."

For more information contact:

COORD3 Metrology LLC

48861 West Road

Wixom, MI 48393

855-4-COORD3 / 248-397-5490

usa.sales@coord3-cmm.com

www.coord3-cmm.com