iXworld - Digital Integration at INDEX

INDEX Multispindle automatic machine MS32-6-flexible and highly productive

INDEX production turning machine C200 tandem-double productivity

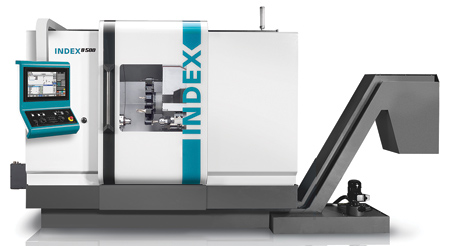

INDEX universal turning machine B500

At EMO 2019, INDEX will showcase innovative machine and cutting technologies. "Visitors will experience the wealth of services available on the INDEX iXworld cloud platform, ranging from machine procurement through operation, right up to service and maintenance," said an INDEX spokesperson.

Seventeen INDEX and TRAUB machines will be displayed. Highlights include: the new INDEX MS32-6 multi-spindle machine, celebrating its world premiere at EMO; and the INDEX B500 and TRAUB TNA400 turning centers, based on the same platform and that can be implemented universally. The INDEX C200 tandem with double spindles offers maximum productivity. The new versions of the INDEX C100 equipped with iXcenter show the capabilities of fully automated production centers.

A variety of other INDEX machines will also be on display outside of the company's booth. One such location is the SONDERSCHAU JUGEND booth (Hall 25, A01), where, together with the assistance of partners from the Nachwuchsstiftung Maschinenbau Foundation, visitors will be able to see a complete process chain, from the initial drawing to manufacture of a Formula 1 model car. The display also includes an INDEX G200 turning and milling center machining the racing car's rims.

iXworld Digital Integration

Alongside all of these machines and technologies, the overarching topic is digitization and the subsequent digitalization. Via ixworld.com, INDEX and TRAUB users can access iXworld and all of the information they need on the company's machinery and technologies, as well as iX4.0, iXshop and iXservices portals. Each of these services provides digital support for the entire process chain.

At the heart of iXworld is the IoT-Platform iX4.0, which integrates INDEX and TRAUB machines in the digital world as digital twins. Since July 2019, INDEX has been supplying new machines with the iX4.0 go starter package on request, which provides free 12-month access to all iX4.0 applications. Due to the open INDEX solution, older INDEX and third-party machines are easy to connect using an IoT connector.

iX4.0 boosts competitiveness through various applications such as AlarmMessenger, which informs the operator of unscheduled downtimes, or Status Monitor, which provides the transparency required when processing MDA and ODA data. iX4.0 apps can also be used for condition monitoring to prevent machine failures before any problems begin. Spindle Check collects information on speed, spindle load, temperature curves, etc., evaluates it and displays it in graphical form. Axis Check performs these tasks for the linear axes.

Intelligent search functions make it easy to purchase toolholders, accessories, clamping devices, spare parts and raw materials-all from a single source-and, if desired, integrated with in-house ERP systems.

"The broad range of products and services available in iXshop is constantly being expanded, for example, by integrating online marketplaces such as that of Klöckner & Co, the digital pioneer in the steel industry, and also by including numerous brand stores offering high-quality complementary products," said the spokesperson.

iXservices is the INDEX service portal for managing all machines, including those from third-party suppliers-including fault, repair, maintenance and care management. An interactive 3D machine model that aids users in identifying and ordering spare parts saves time. Remote access using smart devices and the teleservice is also available, now using a prepaid system and smartphones in order to avoid costly licensing.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

www.index-usa.com

EMO 2019 - Hall 17, Booth D03