Power Automation's PA FDL operator panel alongside the legacy Fadal panel. The PA FDL operator panel is enhanced with advanced HMI features such as a high resolution 17" touchscreen and an ergonomic articulated keyboard. The layout, controls, buttons and shortcuts are organized and labeled in the familiar fashion so operators are immediately confident and comfortable.

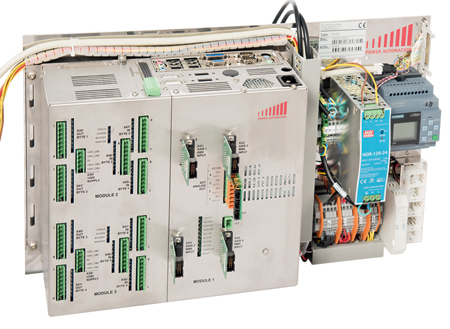

The closed cage design of the computer that powers the PA system protects it from harsh factory environments.

"The user community of Fadal's legacy VMC machines is grappling with challenges of creeping end of life technology, cost of ownership and competition from shops with state of the art equipment," said a Power Automation America, Inc. (PA) spokesperson. "Although the iron itself remains viable, the 1980's era card-based control system lacks the processing speed and flexibility to support current generation software. The high cost of maintenance, replacement cards (when available), downtime and reduced efficiency is pressuring many companies to look for new solutions."

CNC retrofit solutions, which offering various degrees of modernization, are an alternative to complete replacement and have been available for some time. The complete cost of a retrofit involves purchasing a retrofit control, hardwire installation, operator training, possible rewriting of Fadal programs and transition downtime. When total cost is weighted against the extended lifespan, retrofitting often does not calculate to an attractive ROI.

A new Fadal turn-key retrofit solution (PA FDL) based on emulation technology recently introduced by PA brings another option for the 30,000+ Fadal VMC community.

Emulation Software Approach

"Unlike other retrofit controls, the PA FDL is the first open architecture, software-based CNC," said a company spokesperson. "Using emulation technology, the PA FDL actually behaves like the legacy Fadal CNC." The panel layout and labeling has been created in same familiar style using an industrial quality 17-inch high resolution touchscreen with attached articulated keyboard. Operators can step up to a newly installed PA controller and confidently run the equipment exactly as they are accustomed. The PA Fadal turn-key retrofit solution is capable of running existing Fadal programs (Format 1 and Format 2) without rewriting.

The PA FDL includes new advanced functions that bring the system current with industry standards, including MTConnect interface and future Industry 4.0 requirements. The system integrates with modern manufacturing offices, contributing to shop floor efficiency.

Back Online in a Day

Installation of retrofit CNCs typically require complicated re-wiring due to connector incompatibility, resulting in engineering cost and lengthy production downtime. The plug-compatible design of the PA FDL eliminates these hurdles and fast tracks installation. Installation requires no specialized skills or tools and typically takes 2-3 hours from start to finish. Less than a day of downtime is standard to complete the entire retrofit.

More Efficiency, Better Part Finish

"The most exciting feature of PA's Fadal turn-key retrofit solution is its ability to improve the machine's efficiency and performance," said the spokesperson. "The advanced software empowers the machine to move faster and with greater precision, producing smoother finishes with less wear and tear on the equipment. Fadal machines retrofitted with the PA FDL report high productivity gains."

For more information contact:

Power Automation America, Inc.

8601 Jameel Road, Suite 140

Houston, TX 77040

713-263-9400

sales.america@powerautomation.com

www.powerautomation.com