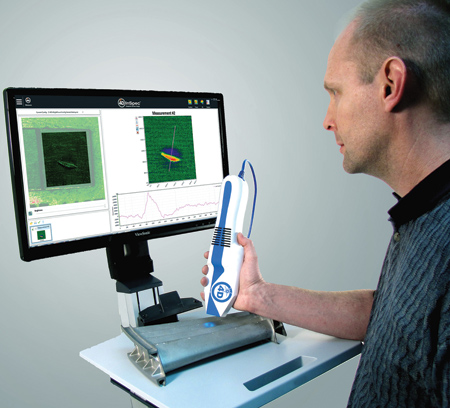

The 4D InSpec handheld surface gauge that measures machined surface defects and features with repeatable, micrometer-level resolution

The 4D InSpec brings micrometer resolution surface measurement to the factory floor. Inspectors can directly measure components of all sizes. Image Courtesy of StandardAero.

"4D Technology has announced the 4D InSpec Surface Gauge, the first handheld, non-contact instrument that measures precision machined surface defects and features with micrometer-level resolution," said a company spokesperson.

The 4D InSpec employs 4D's patented technology which enables rapid measurements that are unaffected by vibration present in most manufacturing environments. QA/QC personnel using the 4D InSpec can take repeatable precision surface measurements on the factory floor, machine shop and field service environments.

"The 4D InSpec addresses a compelling need in precision machined surface measurement: to bring affordable, easy-to-use, quantitative metrology to where samples are located," said Kevin Harding, Principal Engineer at GE Global Research. "We have worked with 4D to develop the 4D InSpec and are excited about what this new technology will mean for GE processes, our suppliers and our customers."

Precision machined surfaces on turbine blades, drive train components and other critical parts may incur damage during production and may wear and corrode from use and/or environmental exposure. These surface defects can cause system failures with significant financial consequences and even catastrophic, loss-of-life events.

"Until now, QA/QC personnel have relied on visual comparison techniques to determine the severity of surface defects," said a spokesperson. "These methods, however, are not precise or repeatable, which can result in missed defects and, more frequently, costly rejection of parts that actually meet specifications. Nanoscale surface metrology systems can provide more reliable data, but these systems are too expensive, slow and susceptible to environmental factors for use on the shop floor. Such instruments are also typically mounted in workstations that limit their capability to measure large components or to image defects in tight corners. Inspectors must create plastic/rubber replicas of these surfaces, which can then be measured - a costly and time-consuming operation," said the spokesperson.

With the 4D InSpec, precision surface measurement is accomplished by enabling direct inspection of large and small components, right on the shop floor. Rugged and lightweight, the handheld gauge has a single cable tether to its computer and is designed to handle the rigors of daily use. The system measures surface defects between 0.1 and 100 mils (2.5 to 2,500 micrometers) deep on a wide variety of part geometries. Its unique design makes it easy to access tight corners or reach across large surfaces. A "fold mirror" attachment enables borescope-like access to features without direct line of sight.

"The 4D InSpec is an innovative measurement system that the aerospace industry has needed for years-beyond years," said Sean MacKendrick, Production Engineering Manager at StandardAero, one of the aerospace industry's largest independent maintenance, repair and overhaul (MRO) providers.

The 4D InSpec installs in minutes and features an intuitive, touchscreen interface for set-up, operation, analysis and report generation. Its easy-to-use software automatically finds critical features and calculates height, volume, area, slopes and location. Operators can quickly select 2-D traces or 3-D plots to view feature details. The system also supports network or USB data transfer to QC systems for rapid pass-fail analysis and historical data tracking.

"The 4D InSpec's performance and affordability enable production and repair facilities of all sizes to employ quantitative, high resolution measurement," said James Millerd, President of 4D Technology.

A complete 4D InSpec system includes the handheld gauge, computer, touchscreen display and software. The gauge can also be mounted in a microscope stand configuration or on a robotic manipulator for highly-repeatable QA/QC, or for automated measurements of complex components. An optional, mobile workstation with rechargeable, 8-hour battery and integrated touchscreen is available.

For more information contact:

Mike Zecchino

Marketing Communications Manager

4D Technology Corporation

3280 E. Hemisphere Loop, Ste. 146

Tucson, AZ 85706

520-975-1345

info@4dtechnology.com

www.4DInSpec.com