technotrans AG to Exhibit Spray Lubrication System at FABTECH

November 9, 2015For the first time ever, technotrans AG from Sassenberg in Westphalia (Germany) will present its products at FABTECH from November 9-12th in Chicago, booth N-3091. The company will present its complete range of solutions for punching and forming applications. With spray.xact, technotrans offers metalworking companies several versions of its mist-free spray lubrication system. The new, cost-efficient version spray.xact is particularly suitable for smaller applications.

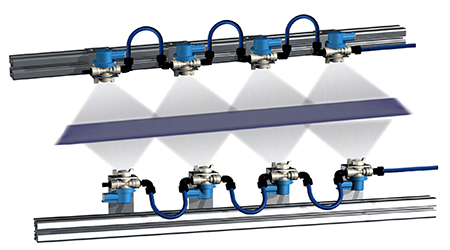

technotrans, as a full-line company, offers a complete range of products for the lubrication of coils, blanks or profiles with emulsions, oils or anti-corrosion agents. The spray.xact system does not require any compressed air and, consequently, no exhaust system is necessary, making the system highly cost-efficient. "In order to round out our offer, we have developed our new spray.xact easy version with up to four nozzles," said Alois Scharf, head of the ink & fluid technology business unit of technotrans. The placement of the spray nozzles in the press is flexible, which is why the cost-efficient version is suitable for all types of applications on a smaller scale. Metalworking companies benefit from all of the advantages of the unique spray lubrication system. Due to its special, high frequency valves, the spray.xact system does not require any compressed air. The system is nearly mist-free so that there is no need for an exhaust system. The application of the oil can be controlled in a highly precise and comfortable manner. All of these features ensure the high economic efficiency of the low-wear and low-maintenance system.

An increasing number of users and press manufacturers apply spray lubrication solutions made by technotrans. This also applies to the new spray.xact reflection, which has been developed particularly with automatic punch presses in mind. "Thanks to the reflection surface, the oil is distributed even more finely so that a mere wisp of oil is applied," said Scharf. Indirect lubrication is particularly suitable for the high-volume production of small pieces, e.g. plug contacts.

As of now, the self-developed nozzles of all of the spray.xact models will be optionally equipped with an optimized monitoring system. Even spray pattern deviations that are caused by a single nozzle will be identified with an even higher level of accuracy, thereby minimizing downtime.

Cooling solutions in the focus

In addition to several variants of its spray lubrication system, technotrans will also present its successful cooling solutions in booth N-3091 during its debut at FABTECH. Of particular interest are the small and large versions of the active and passive cooling systems. Modular combination units replace several peripheral units for the cooling, conditioning and filtration of cooling lubricants. technotrans offers a wide range of cooling systems from 0.1 kW up to 600 kW. The cooling systems are specifically adapted to the customer requirements, and the entire process is supervised by technotrans from the initial idea up to its implementation in close co-operation with the machine manufacturer. With this extensive range of possible solutions, technotrans presents itself as true full-line provider for the tool manufacturing industry.

The technotrans group focuses on applications involving liquid technology as its core competence. With 22 sites and more than 780 employees, the company has a presence in all major markets worldwide.

For more information contact:

technotrans America

Thomas Carbery

Vice President - Sales

847-227-9021

www.technotrans.com

FABTECH 2015 Booth N-3091

< back