3D Visual Tracking

November 1, 2019

FANUC LR Mate 200iD Clean Room lineup

LR Mate 200iD 3D part orientation

FANUC LR Mate 200iD-M-1iaSL Grouping

FANUC LR Mate 200iD using force sensing for deburring

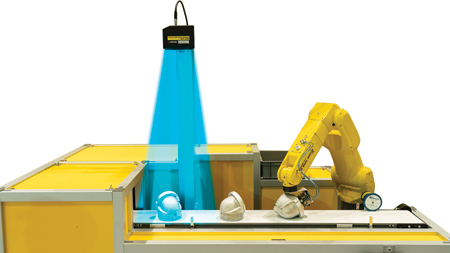

FANUC America recently demonstrated 3D visual tracking with its LR Mate 200iD robot. A FANUC LR Mate 200iD/7L used an overhead mounted 3DV/400 vision sensor to find and track parts moving down a conveyor. The robot picked a part and placed it into a bin. The system highlighted the speed and accuracy of the 3DV/400 vision sensor and the ability to detect the 3D orientation of a workpiece.

FANUC 3DV/400 Vision Sensor

The 3DV/400 vision sensor is lightweight and can be used as a fixed or robot mounted 3D vision camera. The 3DV/400 offers single snap 3D image acquisition, enabling faster bin picking and applications such as line tracking. "Compared to conventional 3D vision sensors it provides better acquisition of shiny parts," said a FANUC spokesperson. It also offers a solution for glare caused by halation. The 3DV/400 is part of FANUC's iRVision system, a fully integrated and complete machine vision system for robot guidance and inspection available on all FANUC robots. FANUC designs all of the hardware and software specifically for FANUC robots, providing customers solutions to meet their production needs.

FANUC LR Mate 200iD Robots

The family of LR Mate 200iD robots is a versatile solution for a range of manufacturing operations that require access into small spaces. A very slim (human size) arm and an optional bottom cable exit minimizes interference with peripheral devices. The LR Mate 200iD robots offer a "best in class" work envelope for both upright and invert mount installations. The LR Mate 200iD robots are also available with ISO Class 4 clean room and food-grade variants for food handling and healthcare packaging applications.

LR Mate 200iD features and benefits:

- Slim arm and compact footprint minimizes interference to peripheral devices in narrow spaces

- Available in three variations: standard, short and long arm

- Four to 7 kg wrist load capacity with 6-axis articulation

- Work envelope simplifies system layout

- Fast joint axes speeds maximize system throughput

- Integrated 24VDC power, signal and air for easy end-of-arm-tool connection

- Integrated through-arm cable option for iRVision, force sensing, Ethernet and auxiliary axes

- Flexible mounting (upright, invert, angle)

- High rigidity and advanced servo technology enable smooth motion at high speeds

- Easy integration into machines

- Features lightest mechanical unit in its class

- IP67 rating allows operation in factory environments with dust and oil mist.

For more information contact:

FANUC America Corporation

3900 West Hamlin Road

Rochester Hills, MI 48309-3253

888-FANUC-US (326-8287)

www.fanucamerica.com

< back