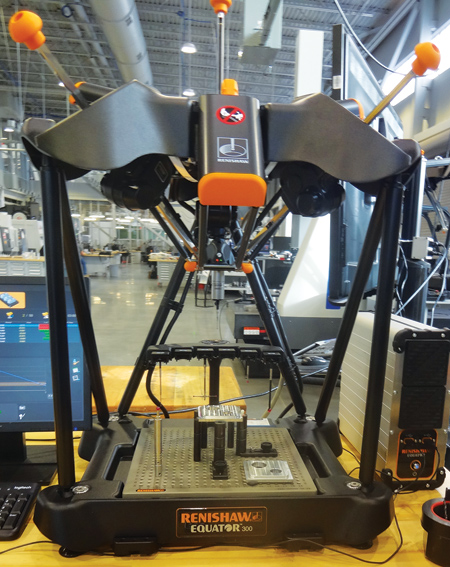

Instructors often travel to schools with the Renishaw Equator comparative gauge to perform inspections for free. It is an effective recruitment tool for students.

Greenville Tech uses this Haas 20Y Y-axis CNC lathe with live tooling for educational purposes and for collaborating on projects with partners.

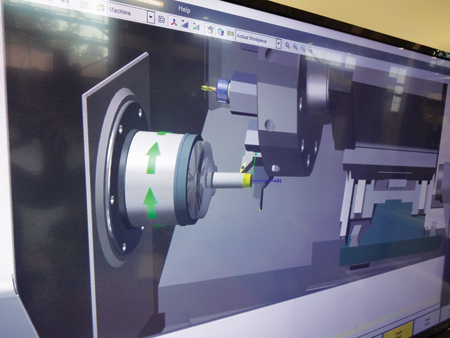

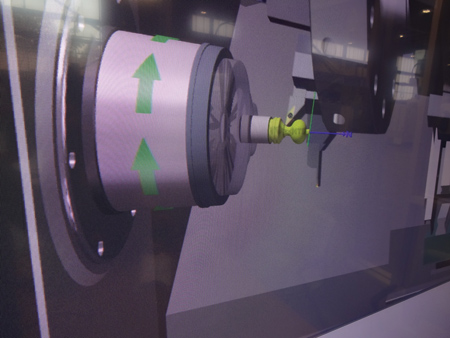

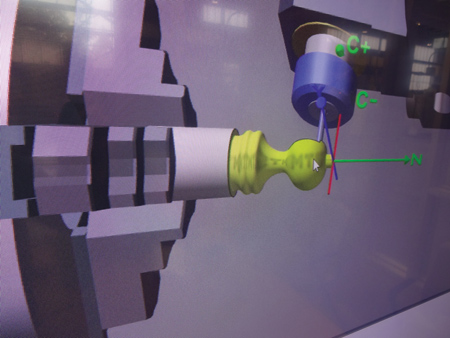

At a recent Lunch and Learn for students, instructors helped students access a Mastercam program to create chess pawns: Loading the stock into the program, opening the hydraulic chuck and machining the pawns on the Haas 20Y lathe.

The CRYSTA-APEXS CMM is the focal point of the only school-based metrology lab in the U.S., funded, in part, by the Gene Haas Foundation.

The 100,000 sq. ft. facility includes state-of-the-art classrooms, and an expansive machine shop that educates 4,000 to 5,000 students per year.

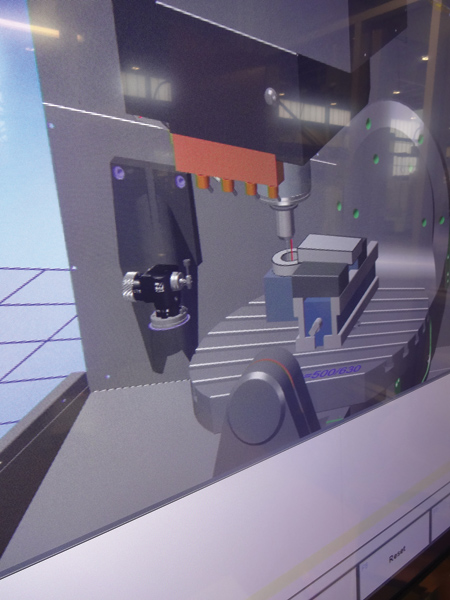

The software contains a Simulator function, which is simple to teach and can be used to virtually machine a part. It includes full 3D graphics and the ability to mimic actual machining processes which make lessons fun and relatable for teachers and students. Greenville Tech utilized this feature when machining the chess pieces during the event.

The U.S. is currently the home of the world's largest manufacturing economy, but a retiring workforce coupled with a low influx of new hires leaves the position vulnerable. Within the next 10 years, 3.5 million manufacturing jobs need to be filled. Dr. Jermaine Whirl, Vice President for Learning and Workforce development at Greenville Technical College (Greenville, SC), is committed to working with manufacturing companies to train individuals to fill these jobs and sustain the United States' position as a top power in the manufacturing industry.

Greenville Tech offers a variety of programs including associate degrees, professional certificates, continuing education, summer camps for kids, as well as specific training for high school teachers in critical need subjects (i.e. robotics, machining, engineering, etc.). Recently, the college received approval to offer an applied baccalaureate degree in advanced manufacturing technology, which differs from traditional instruction. Rather than limiting students by relying on theory in a formal lecture hall, Greenville Tech brings undergraduates out of their seats and into the field where they can practice hands-on skills and gain real-world experience.

"Governor Henry McMaster came to our Center for Manufacturing Innovation in August to sign legislation permitting Greenville Technical College and the state's other technical colleges to offer an applied baccalaureate degree in advanced manufacturing technology," said Whirl. "This degree will allow us to deliver what employers need."

In 2015, the college received $25 million in funding from Greenville County to expand its classroom and laboratory/manufacturing space. The result is the Center for Manufacturing Innovation (CMI), a 100,000 sq. ft. facility that contains state-of-the-art classrooms, including the Wells Fargo Theater, an amphitheater-type classroom with a big screen. The facility also contains 3-axis and 5-axis Haas machining centers, Haas turning centers with live tooling, Renishaw probes and the only school-based metrology lab funded in part by a grant from the Gene Haas Foundation. The Foundation donated $2 million to Greenville Tech's manufacturing program.

Greenville Tech is part of the Haas Technical Education Center (HTEC) Network, a community of 2,200 schools, colleges and universities, and 95 technical partners started by race car enthusiast and owner of Stewart-Haas Racing and Haas Automation (Oxnard, CA), Gene Haas. This network is able to provide a top-notch education for manufacturing students through the latest Haas machines, tooling and related equipment and materials. HTEC's member companies often partner with schools to help prepare students for real-world manufacturing applications. Among those member companies, many have partnered with Greenville Technical College, including CNC Software, Inc., (Tolland, CT, developers of Mastercam CAD/CAM Software), Haas Automation, Renishaw, Inc. and Mitutoyo.

According to Kelvin Byrd, Interim Director of the Center for Manufacturing Innovation at Greenville Tech, these partnerships are crucial to provide real-world scenarios to students and to forge strong relationships with industry necessary to get the job done. They also help Greenville Tech with its prototype and manufacturing services, which can provide full-service manufacturing or specific facility and/or equipment use or leasing. Byrd gave an example of how leveraging these partnerships helped solve a customer's challenge. "TTI Anderson had a part that needed to have a bore, but they did not have a big enough bore size in their machine, so they called us," he said. TTI is a Sandvik Coromant customer. Greenville Tech worked with an associate of Haas who was teaching at the college, staff from Mitutoyo, and an engineer from TTI to machine a part that had the specifications needed. It was done in a day. Byrd pointed out that anytime a project like this occurs, no one goes above and beyond to lend technical support more than their local Mastercam Reseller, Barefoot CNC (Morganton, NC). It is the software that ties all of these machines together and the on-site advice and consultation shared by the experts at Barefoot that helped to unlock the software features that best worked with all machines.

"I try to tell people the top three things we are doing in here is partnership, partnership, partnership. If we did not have the partners we have, we would not be successful. I do not push software, but I tell them if you want support, if you are doing molds, if you are doing complex geometry, I would go with Mastercam," Byrd said.

Recently, the college held a Lunch and Learn, hosting approximately 400 high school students, where the Mastercam software took center stage. Greenville Tech partners worked the machines, answered questions and engaged the students. CMI instructors had a unique approach to make the content appealing for students. "We ran chess pieces. Watching a part being created is one thing, but the kids were active participants, machining the chess pieces themselves. They went into the program, pulled it up, loaded the stock, opened the hydraulic chuck, put it in and machined it. And they are just hooked," said Byrd.

The software contains a Simulator feature, which is simple to teach and can be used to virtually machine a part. It includes full 3D graphics and the ability to mimic actual machining processes, which make lessons fun and relatable for teachers and students. Greenville Tech utilized this feature when machining the chess pieces during the event. After a practice round using the software, students were able to machine an actual pawn on a Haas ST-20Y turning center.

Byrd shared that the software is an obvious choice for educators; the vast majority of manufacturers who will be hiring their students are using it. His instructors love Mastercam Mill-Turn and try to impress its importance on students. He said, "That is what many other software programs do not have, this simulation. Mastercam is doing it. It simulates exactly what the CNC machine is going to do."

Each summer, Greenville Tech runs a class that machines NIMS-approved parts for teachers. "The instructors do simulation and then we go out to the machine. They are trying to use NIMS as the benchmark for us to aim for," said Byrd. He also travels with the Renishaw Equator high speed comparative gauge. "The high school that does not have enough money to get an Equator? We are going to take it there and check their parts for no charge. Because it is recruitment; when students see that automation, they want to enroll in the classes with more technology," he said.

Mastercam software helps make teaching the students that come through Greenville Tech every year engaging and streamlined. Instructors also use the software in Greenville Tech's summer camp for girls. The girls operated the software to design and build a plastic mold with the inscription "Girls Rule." Instructors took the girls to a candy store, where they melted chocolate to pour into the molds and make original chocolate coins. Throughout this activity, the girls learned about the math, CAM set-up, and the technical process, while also enjoying delicious chocolate.

Because females are still a minority in STEM-related careers, Byrd hopes programs like these will help to encourage women to pursue this profession. "We are letting the girls know women can succeed in this field if you want it and if you like it," he said. With the high demand for skilled workers, Byrd knows that recruiting from previously ignored groups is imperative. He regularly recruits people who might have been overlooked for professional training. Though he recruits from underrepresented groups, Byrd maintains a high standard for all students. Drug tests are required, and students must commit to being on time. Every student must be able to do simple math, take directions and exhibit a hardworking attitude. Byrd explained that he needs every single one of his students to be employable and ready to take on a demanding but rewarding career when they finish.

The college continues to support its students even after they leave Greenville Tech. "As they go to work, we follow up 30 days later and sit down with the mentor or supervisor," Byrd said. Not only does this allow the students to come back and work on any issues they may be facing, it also informs the curriculum to tailor the content to real-world situations. The results speak for themselves. In four years, Greenville Tech placed 32 people at a local manufacturing company. Of those, 30 are still employed there. Greenville Tech's program helps provide outreach and open doors for these overlooked groups. "There are still people that want to work and want to learn, and because of their attitude we are getting there. We always want to give them options to increase their skill and education," Byrd said.

Byrd's goal for Greenville Technical College's Center for Manufacturing Innovation is to become a leading name in the industry as a respectable skills-based institute that matches underemployed people with understaffed manufacturing companies. He plans to continue to recruit people from different backgrounds and invites other education facilities to do the same.

For more information contact:

Greenville Technical College

P.O. Box 5616

Greenville, SC 29606

864-250-8000

www.gvltec.edu

CNC Software, Inc.

671 Old Post Road

Tolland, CT 06084

800-228-2877

info@mastercam.com

www.mastercam.com