Inspection Technology for the Aerospace Sector

June 1, 2019

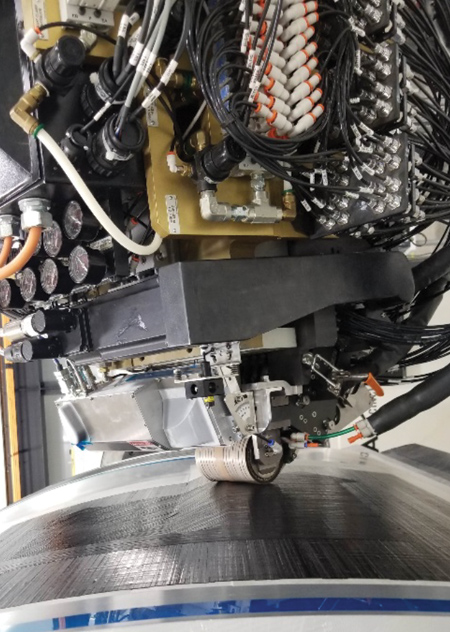

This Fives Viper Automated Fiber Placement machine, integrated with NRC profiling technology, enables high-quality, real-time in-process inspection for the aerospace industry.

As the aerospace industry in Canada and around the world continues to increase its use of automated composite manufacturing techniques to produce large aircraft components, the industry is eager to find solutions to manufacture reliable, safe and cost-effective composite structures. The National Research Council of Canada (NRC) and Fives are working together to improve the efficiency of manufacturing composite parts. They are developing an advanced profilometer that will provide faster and more accurate part inspection.

"Based on an innovative optical technology, the advanced profilometer for composite placement shows considerable advantages over existing inspection technologies used for the same purposes," said a company spokesperson. "This groundbreaking in-process inspection technology will help manufacturers meet strict standards by providing enhanced measuring information without limiting the process functionality. These faster, better measurements will speed up manufacturing processes, reduce the risk of errors and help composite manufacturers be more competitive."

Fives has already started the last testing stage of the next-generation profilometer with customers and expects to begin commercializing the technology before the end of 2019. The NRC and Fives will continue to work together to advance this technology.

For more information contact:

Fives Cincinnati, a div. of

Fives Machining Systems Inc.

2200 Litton Lane

Hebron, KY 41048

859-534-4600

www.fivesgroup.com

National Research Council of Canada

https://nrc.canada.ca/en/

< back