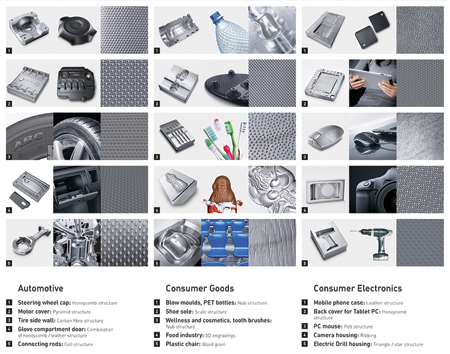

Application example of different surface textures.

The LASERTEC 125 Shape has been designed especially for the texturing of large molds with dimensions up to o1,250 x 700 mm.

LASERTEC Shape technology offers freedom in design for die and mold.

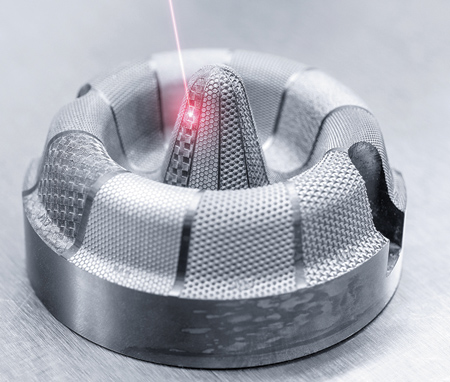

Geometrically defined surface structures can be produced with DMG MORI's LASERTEC Shape series. The LASERTEC 125 Shape is engineered to execute high quality, fine contours and filigree cavities for the manufacture of injection molds, pressing dies, labels and other engravings without any tool wear.

The machine has been designed especially for the texturing of large molds and dies of up to o1,250 x 1,000 mm and workpiece weights of maximum 2,600 kg (with the optional tandem drive). The optional high-speed Z-Shifter increases travel speed in the Z direction from the current 1.5 m/s to 5 m/s, while the laser achieves a pulse frequency of up to 1,000 kHz. Texture quality has been optimized while retaining the high processing speed. This has resulted in up to 69% shorter processing times, resulting in lower costs per part.

Like the smaller LASERTEC 75 Shape, the LASERTEC 125 Shape also combines the stability benefits offered by the monoBLOCK design. It features a compact footprint of 19 sq. m. Travel paths of 1,335 x 1,250 x 900 mm (XYZ) allow this machine to be used for a variety of applications. It can handle maximum workpiece dimensions of o1,250 x 1,000 mm, thus enabling the efficient texturing of large formats. The NC swivel/rotary table is designed for a workpiece weight of up to 2,000 kg. The load capacity goes up to 2,600 kg with the optional tandem drive. The work area offers users optimum accessibility and reduced risk of collision due to its large dimensions.

With LASERTEC Shape's "green" technology, no chemicals are needed for costly and time-consuming etching processes, allowing fast serial implementation of new innovative injection-molded parts. In addition to aesthetically pleasing designs and textures, technically optimized surface structures (optimized flow or durability, for example) can also be tested and implemented.

The dynamics of the LASERTEC 125 Shape, derived from direct drive technology, have now been further enhanced by the optionally available high-speed Z-Shifter. In contrast to the Z-Shifter installed in the standard version with its a maximum speed of 1.5 m/s, the high-speed Z-Shifter achieves up to 5 m/s in the Z direction. "Texturing quality is retained even with the higher feedrate, because the process is supported by an enhanced texturing strategy," said Patrick Diederich, Managing Director of SAUER GmbH. "The high quality of surface texturing achieved by the LASERTEC 125 Shape is the result of state-of-the-art hardware and software components. It is precisely this combination that allows efficient machining of the highest level." A high-precision scanner with digital measuring system and scan speeds up to 30 m/s round off the hardware.

Where the control is concerned, a 21.5" ERGOline multi-touch display provides optimum user comfort. The LASERTEC 125 Shape is equipped with the intuitive and uniform user interface CELOS and a SIEMENS 840 D solutionline with LASERSOFT D software features. These are designed to simplify the creation of contours, lettering, logos and surface structures in 3-D surfaces, cylinders or complex free-form surfaces. The machine program and the optimum texturing strategy can be generated automatically from the 3-D CAD data of the actual workpiece.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

www.us.dmgmori.com