Twin-Spindle Solution for Oil Field Components

February 1, 2019

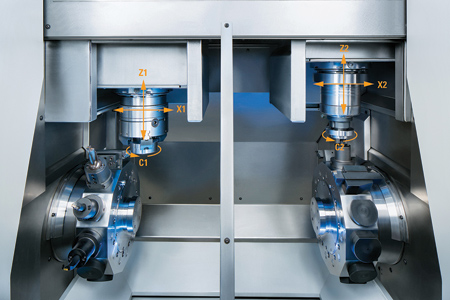

The VL 3 DUO is a complete production system for chucked parts.

The VL 3 DUO is equipped with two separate machining areas to ensure short cycle and set-up times.

The TransLift is responsible for the complete transport of parts and not only takes care of loading and unloading but also changes the parts between the operations.

EMAG, a supplier of manufacturing systems for precision metal components, will feature manufacturing systems for precision metal components with a special focus on the creation of oil field components.

On display will be EMAG's VL 3 DUO, a multi-spindle machine for the productive manufacturing of chucked parts. This twin-spindle machine solution is designed for the productive manufacturing of chucked parts up to 6" in diameter, and integrates all of the most recent EMAG technological developments (including self-loading spindle, the TrackMotion automation system and the modular machine design). "With all of these innovations, the VL 3 DUO is the perfect highly productive manufacturing system while maintaining a minimum footprint," said a company spokesperson.

For more information contact:

EMAG L.L.C.

38800 Grand River Ave.

Farmington Hills, MI 48335

248-996-4703

www.emag.com

HOUSTEX 2019, Booth 2321

< back