Reinventing Workholding Onsite Demos

August 1, 2018

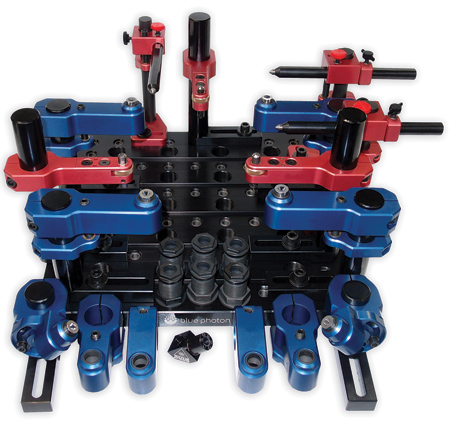

Universal Fixture Kit, entire standard kit shown

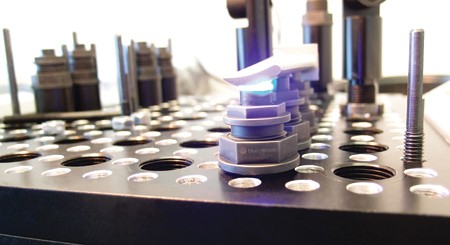

An example of Blue Photon grippers holding a curved part for machining

Blue Photon will demonstrate the advantages of its photo-activated adhesive workholding system at IMTS 2018. "Born in the lab and field-tested in manufacturing plants all over the world, Blue Photon's workholding products are a manufacturers' solution to secure parts for tight-tolerance machining and inspection," said a Blue Photon spokesperson.

"Blue Photon's workholding technology can reduce the number of operations, scrap and labor," said the spokesperson. The process involves applying BlueGrip workholding adhesive to its grippers and spot curing by ultraviolet light for 60 seconds. The part debonds with a 1/4 turn twist of the gripper or hot water soak. The residual adhesive is simply removed by the application with pressurized steam or hot water spray and a light peeling action.

Blue Photon tests have shown that the holding force produced by the grippers can easily withstand the requirements of most machining applications. "The material removal rate can exceed expectations versus mechanical clamping when a hard to hold part is mechanically clamped, as often times the pressure has to be limited to avoid component distortion and marking," said the spokesperson. Blue Photon's system can secure ferrous and non-ferrous materials as well as superalloys, composites, and plastics; allowing for many workholding capabilities including 5-axis machining.

At IMTS 2018, Blue Photon will be introducing its universal fixture kit. This kit allows the user to begin using the workholding system immediately by easily adapting to most parts.

For more information contact:

Blue Photon Technology & Workholding Systems LLC

1002 Industrial Park Dr.

Shelby, MI 49455

855-777-2040

www.BluePhotonGrip.com

IMTS 2018 Level 3, Booth W-431392

< back