Adaptive Machine Offers Multidirectional Flexibility

August 1, 2018

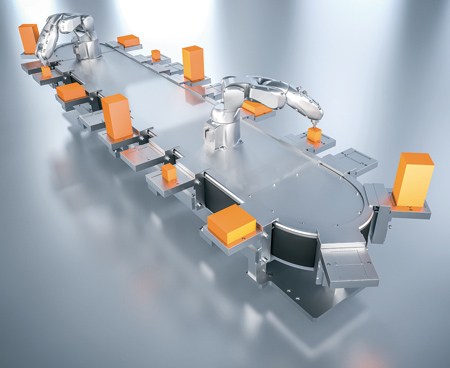

Independently controlled shuttles add to the adaptive machine's flexibility.

B&R Industrial Automation Corp. will introduce track technology with an adaptive machine. An adaptive machine has the capacity to change over on the fly, and moreover, to reconfigure with different production modules on the same base machine platform.

This new generation of production machinery is readily adaptable to constant size and format changes. In addition, it is reconfigurable to unforeseen requirements through corresponding equipment changes, such as replacing a welding module with a forming module.

Adaptive machines are defined by individually controlled modules with multidirectional movement, tight synchronization with other (often robotic) devices and enhanced production flexibility. Adaptive machinery will compare favorably in all aspects of productivity measurement - OEE, ROI, TCO - as lot and batch sizes shrink and throughput (lead time and volume) requirements remain critical.

Technology highlights:

- B&R will introduce advanced track technology that enables the adaptive machine for profitable production down to batch of one.

- Field device for OPC UA: The new X20 I/O system bus controller makes it possible to implement OPC UA communication from the sensor layer to the ERP layer without interfaces.

- Expanded portfolio of modular mapp software components.

- The new mapp RoboX and mapp Technology make it faster and easier to get robotic systems configured and ready for operation.

- Learn about HTML5 based HMI development using the new mapp View. "For the first time, automation engineers have all the tools they need to create powerful and intuitive web-based HMI solutions - without the need to learn HTML5, CSS or JavaScript," said a company spokesperson.

- Learn more about the SafeDESIGNER library for press applications. "B&R is one of the first manufacturers to offer a complete set of the function blocks specified in PLCopen Part 4," added the spokesperson. As a result, users working with safety-critical press applications will have an easier time setting up the necessary safety functions.

- See the live TSN test bed in B&R's booth as well as a presentation by B&R's Business Development Director, John Kowal on "Beyond the Brown-field: How the Adaptive Machine makes IIoT a Practical Reality," on Tuesday, September 11, 2018, at 3:15 PM in the West Building - Level 1 of McCormick Place, IAMD.

For more information contact:

B&R Industrial Automation Corp.

1250 Northmeadow Parkway, Suite 100

Roswell, GA 30076

770-772-0400

www.br-automation.com

IMTS 2018 Level 3, Booth E-134111

< back