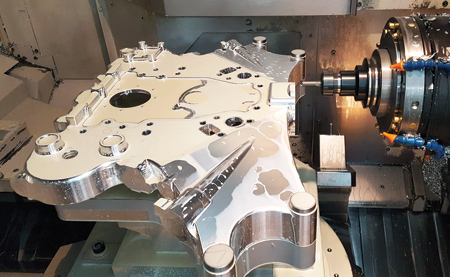

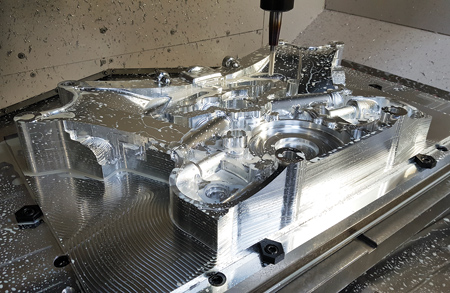

RCR uses a 1/2" 3-flute carbide ball end mill from Benchmark to do roughing and finishing of a pocket. Roughing at 8,000 RPM and 40 IPM, finishing at 8,000 RPM and 30 IPM. This is the third machining set-up and is on the Okuma MA-500HB horizontal.

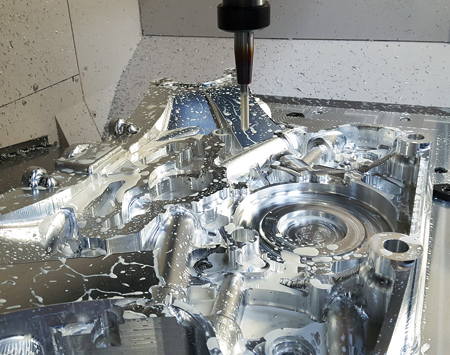

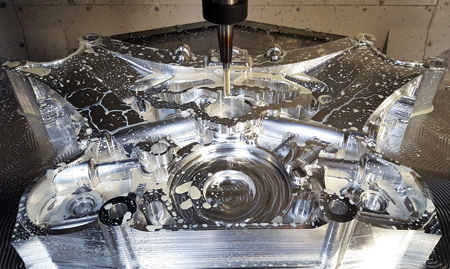

RCR uses the 1/2" 3-flute carbide ball end mill from Benchmark for surface machining.

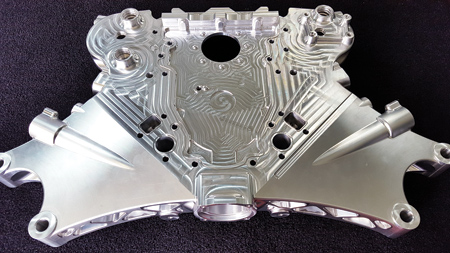

Front and back of the finished motor plate ready to install onto the engine.

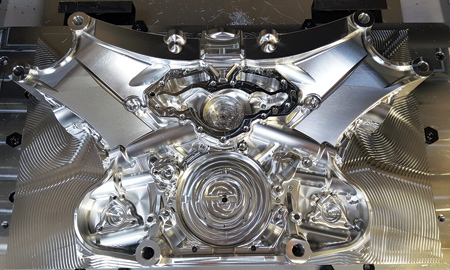

The motor plate after the first set-up has been completed, which required approx. 1,200 different machining operations/sequences.

The first set-up on the Okuma MB-56, running 9,500 RPM and 75 IPM. A 1/2" 3-flute carbide ball end mill from Benchmark performs 3-D surface machining.

Mike Creed creates the CNC program for machining the motor plate.

Victory lane in Daytona at the Rolex 24hrs of Daytona race. The Cadillac team won the race. RCR made a total of 14 motor plates for three Cadillac teams.

The Cadillac race car.

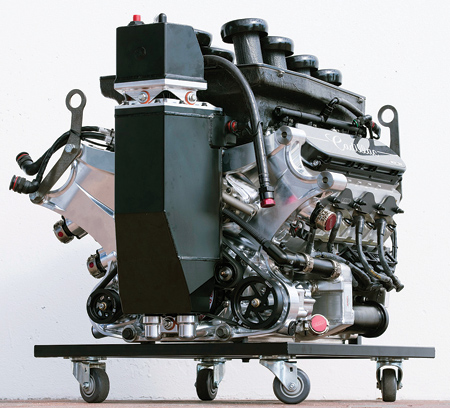

The complete Cadillac V8 engine. In addition to the motor plate, RCR also manufactured about 50 other billet machined parts for the engine in the Cadillac race car, including valve covers, rocker bars, pulleys, oil tank parts and oil pump parts and more.

The complete Cadillac V8 engine in the car. Jeff Gordon was one of the drivers at Daytona and part of the winning Cadillac team.

Richard Childress Racing (RCR) builds race cars from the ground up in a fully-integrated, vertical manufacturing operation at its 17-building, 52-acre campus in Welcome, NC. RCR has a culture focused on innovation, and its engineering team uses cutting-edge technologies to continuously improve the performance of its race cars.

One of RCR's most recent projects was a motor plate for a 6.2L V-8 engine in the Cadillac Dpi-V.R., a prototype race car. The car competed in the 2017 IMSA WeatherTech Sports Car Series. The Cadillac engines are built by ECR Engines, LLC, a division of RCR.

The motor plate needed to fit specific criteria, and posed several manufacturing challenges:

- Overall short lead time from start of engine design to completed engine ready for competition

- Very complex design geometry to manufacture into the part

- Very tight tolerance and surface finish requirements.

The motor plate design called for a 4" x 18" x 30" billet 2024 aluminum block with a starting weight of 211 lbs. RCR uses PTC's Creo 3.0 for both product design and toolpath programming on its CNC machines.

For machining these complex projects, RCR relies on its Okuma MB-56V 3-axis vertical and Okuma MA-500HB horizontal, both outfitted with high speed machining options along with Renishaw probing and Chick workholding accessories.

To manufacture the motor plate, RCR used 104 different tools to generate over 2,000 different individual machining operations/sequences. These were compressed into five different set-ups: two set-ups on the MB-56 vertical and three set-ups on the horizontal. Finished part weight is 31.8 lbs.

Tooling consisted of the following:

- Custom 2-1/2" dia. T-slot cutter from AB Tools

- Kennametal TF drills and Kennametal 10xD 1.000 dia. KSEM drill

- Benchmark 3-flute ball end mills for surfacing

- Kennametal 3-flute high helix finish end mills for pockets and profiles.

"This solution worked very well, " said Rocky Helms, Manufacturing Manager, RCR. "We achieved extremely nice surface finishes on the drilled holes, and it held size very well. We achieved a nice surface finish on all surfacing using the 3-flute Benchmark ball end mills for aluminum, in addition to superb finishes on all pockets and profiles using the 3-flute AADE line of Kennametal end mills for aluminum."

In addition to the motor plate, RCR also made about 50 other billet machined parts for the engine in the Cadillac race car, including valve covers, rocker bars, pulleys, oil tank and oil pump parts and more.

The MB-56V features a rigid double column structure along with Okuma's Thermo-Friendly Concept as standard for dimensional stability over long, continuous runs. RCR utilizes a 15,000 RPM high speed machining option on the MB-56V. RCR's Okuma MA-500HB features 50 taper, 12,000 RPM high speed machining option.

RCR manufactures various engine and car related components for three NASCAR racing series. All pit gun and race jacks are produced in house. Cam shafts, also produced in house, have also gained a productivity boost. The old process and tooling took 3 hours to produce one cam; the new process and tooling takes only 40 minutes per cam.

Additional capabilities at RCR include:

- Zeiss quality control technology

- Omax waterjet

- Sodick wire EDM

- JobBoss shop management software

- NC Simul software for toolpath simulation.

RCR manufactures, maintains and races three entries in the Monster Energy NASCAR Cup Series, five entries in the NASCAR Xfinity series. It also manufactures chassis and components for various Alliance teams in both series. It has engine lease programs for all NASCAR series, and supplies engines for all GM teams running a Cadillac in the Prototype series in the IMSA WeatherTech Sports Car series.

Founded in 1969, Richard Childress Racing is one of the largest and most storied organizations in NASCAR competition. RCR currently fields three teams in the NASCAR Cup Series and five teams in the NASCAR XFINITY Series.

Throughout its history, RCR has accumulated a total of 17 championships and more than 200 victories across NASCAR's top three series, including two Daytona 500 wins and three Brickyard 400 victories, two of the sport's crown jewels of competition. RCR was the first organization in NASCAR history to win championships across all three national touring series.

For more information contact:

Richard Childress Racing

www.rcrracing.com

Richie Gilmore

ECR Engines LLC

P.O. Box 1249

Welcome, NC 27374

www.ecrengines.com

Okuma America Corporation

11900 Westhall Drive

Charlotte, NC 28278

704-588-7000

www.okuma.com