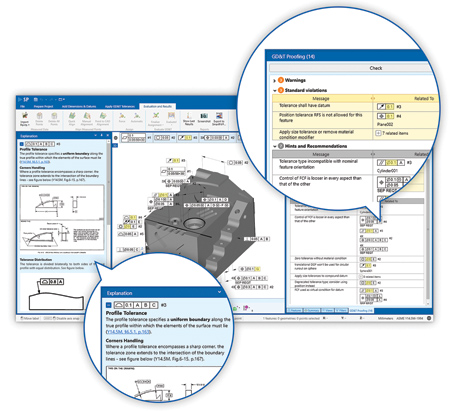

EVOLVE Design provides best practices GD&T guidance

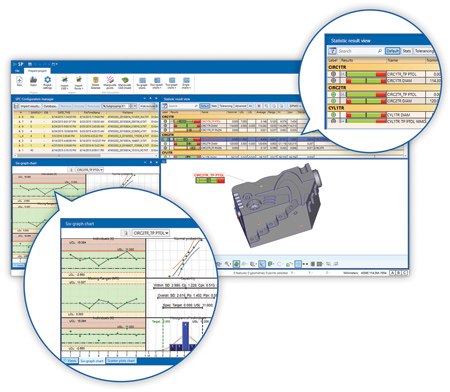

EVOLVE SPC helps track the manufacturing process

KOTEM, a division of Quality Vision International (QVI), offers three new additions to its EVOLVE software family: EVOLVE Design, EVOLVE SPC and EVOLVE DataPreparation. These applications were created to enhance communication of Geometric Dimensioning and Tolerancing (GD&T) tolerances throughout the enterprise manufacturing process.

"Most product designers use CAD to create perfect parts, but they also provide tolerances so manufacturing can build those parts and keep them within design specifications," said a company spokesperson. "The transition from the perfect world of CAD to the real world of manufacturing has always been a challenge.

"During the design process, product designers typically use their own interpretation of GD&T standards, but before actual parts can be built, manufacturing must revisit and reinterpret the GD&T standards (again). To complicate matters further, the quality department must inspect the production parts to ensure they are built to specifications, and in so doing they revisit the GD&T standards for at least a third time. All these instances of interpreting and reinterpreting GD&T standards creates opportunities for errors and uncertainties to creep into the process, often missing the product designer's original design's intent and costing time and money."

KOTEM's solution is to use the same GD&T engine throughout the entire process, from product design, to manufacturing, to quality control. These three new software products, EVOLVE Design, EVOLVE SPC and EVOLVE DataPreparation, all use a common GD&T engine, to ensure consistent interpretation of GD&T standards.

- EVOLVE Design supplies the GD&T proofing needed by product designers, providing best practices guidance while helping the designer maintain adherence to GD&T standards. EVOLVE Design uses the same GD&T engine used in SmartProfile, KOTEM's application to evaluate part compliance with GD&T tolerances.

- EVOLVE SPC provides state-of-the-art statistical process control tools to manage the manufacturing process. Integration of 3-D CAD model, data and graphics allows clear visualization and correlates measured points to the location on the CAD model and the same points on a control chart or table. This is especially helpful when reviewing and analyzing many parts and/or measured points. A full database implementation allows long-term trend studies and manufacturing analysis of potential problem areas. Additionally, non-CAD data points can be imported and converted to model-based data points.

- EVOLVE DataPreparation acts as a bridge between advanced measurement systems that generate a large number of measured points, preparing these points to be processed and analyzed for GD&T evaluation by KOTEM's SmartProfile. This enables KOTEM's customers to use the best measurement technologies options, to help maximize speed while improving accurate results.

With these three additions to the EVOLVE family, KOTEM offers an end-to-end solution for product tolerancing needs from proofing to evaluation and compliance, all critical to manufacturing success.

For more information contact:

KOTEM

info@kotem.com

www.kotem.com