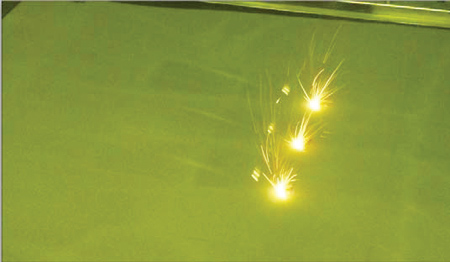

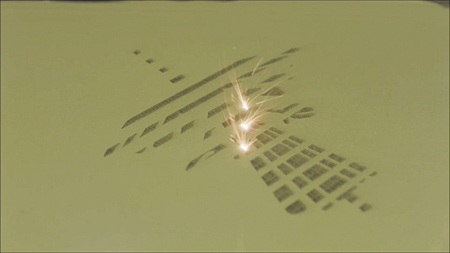

The Sodick OPM grows three separate parts simultaneously with the new Parallel Mode.

Parallel Mode automatically optimizes the laser path, enabling three locations to sinter simultaneously, even on the same workpiece.

When the OPM was first released, the expected sinter time for this part was 22:05 hours. With Parallel Mode, the expected sinter time is now below 9:50 hours.

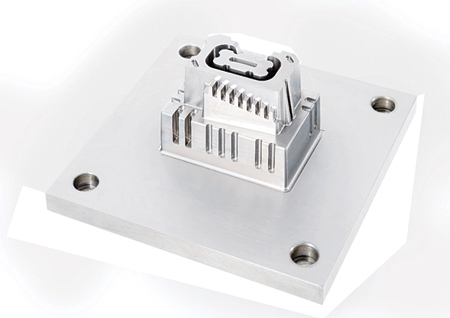

Metal 3-D printer manufacturer Sodick has announced the development of new 3-D printing technology called Parallel Mode. Sodick first launched its 3-D metal printer, the OPM250L, at IMTS 2016. Since then, Parallel Mode's technology has redefined the machine's process speed.

Parallel Mode grows parts at three locations simultaneously; the OPM requires only a single beam to accomplish this task. That is because laser sintering equipment must take fumes and shape deviation into consideration when generating the laser path. For this reason, the laser unit is not necessarily utilized at full capacity during processing. In Parallel Mode, the OPM makes optimal use of the laser unit by targeting multiple locations simultaneously.

Parallel Mode is suited to a wide variety of applications and can be used not just to create replicas of the same part, but also to produce singular large parts in less time. "Unlike multi-beam designs, which often utilize separate work envelopes, Parallel Mode is not limited to one beam per quadrant," said a company spokesperson. This means that a workpiece covering only one part of the worktable will benefit from Parallel Mode just as much as if it had covered the entire table.

Parallel Mode additionally benefits from a recently upgraded fume collector issued standard with the OPM. The fume collector lasts significantly longer than the previous iteration, allowing it not only to run longer between maintenance cycles, but also to easily accommodate the fumes produced by Parallel Mode's increased productivity. Altogether, these advancements fit within Sodick's larger strategy of optimizing the central technologies of metal 3-D printing, allowing the user to reliably print finished, high-density parts that would otherwise be impossible to produce.

For more information contact:

Sodick Inc.

1605 N. Penny Lane

Schaumburg, IL 60173

847-310-9000 / 888-639-2325

info@sodick.com

www.sodick.com