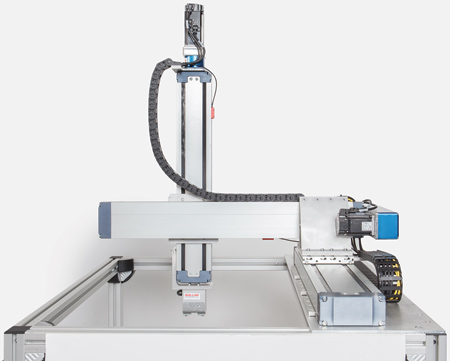

Rollon's Motion Box 3-axis Cartesian robot system

Rollon Corporation has launched Motion Box, a pre-engineered cartesian robot system designed to deliver users six different motion profiles that can be set up and running in a couple of hours.

"Motion Box covers everything from the human-machine interface (HMI) on one side to the output of reliable motion on the other end," said a company spokesperson. "Even the cable management is included, helping reduce the difficulty of setting up the system."

The initial system set-up is already complete so end users can get parts moving in a reliable and repeatable manner. Motion Box has six pre-programmed motion profiles to suit more than 80% of all Cartesian motion applications:

- 12" x 12" x 12"

- 16" x 16" x 16"

- 20" x 20" x 20"

- 30" x 30" x 20"

- 40" x 40" x 20"

- 60" x 40" x 20"

After defining the available space and required motion footprint, users check the load and speed requirements. Whether the load is 5 or 50 kg, maximum speeds are based on this variable. Load and speed charts help make it simple to determine travel times for X, Y and Z axes so that the correct system matches the application.

"For example, with the smallest work envelope of 12 inches x 12 inches x 12 inches, it takes roughly half a second to move from corner to corner, whereas a larger motion envelope might take 2 or 3 seconds to make the same move, depending on the load," said the spokesperson.

Rick Wood, Managing Director, Rollon Corporation, said, "Motion Box is a pre-engineered Cartesian robot with the mechanical system and controls already in place and ready to go. Using an out-of-the-box Cartesian like Motion Box enables users to work with a single vendor for advice and troubleshooting needs, with just one part number per item. Buying a part and buying a robot become a similar task, making both initial specification and set-up fast and easy."

Motion Box also offers flexible integration options via an Ethernet connection. The Cartesian robot system can connect to wider automation setups using EtherNet/IP, DeviceNet, TCP/IP, CC-Link, Profibus and ProfiNet, as well as company networks and control architectures. A streamlined control system also helps simplify ease of use. Motion Box incorporates the Q-Motion Controller from Mitsubishi Electric, which features four-axis motion control, energy-efficient drivers, integrated I/O and network access and an efficient HMI setup.

For more information contact:

Rollon Corp.

101 Bilby Rd., Ste B

Hackettstown, NJ 07840

973-300-5492

info@rolloncorp.com

www.rolloncorp.com