(l-r) Frank Ostertag and Biljana Sevdic, production planners at the headquarters of the CeramTec group in Plochingen, Germany.

While CeramTec machines numerous workpieces with conventional grinding machines, the ceramic specialists now also have three DMG MORI 5-axis ULTRASONIC machines at their disposal.

5-axis simultaneous machining by means of ultrasound has significantly extended the ceramic product portfolio of CeramTec.

Because of the ULTRASONIC technology, the portfolio of CeramTec also comprises highly complex workpieces, so that the sales department can offer additional solutions.

More than 100 years experience in production and development, as well as more than 3,600 employees, characterize the CeramTec Group with headquarters in Plochingen, Germany, as one of the leading international manufacturers of technical ceramics. More than 10,000 different products and components are supplied by the ceramics experts to customers from the automotive industry, electronics, energy and environmental engineering, mechanical as well as medical engineering. Among other reasons, the broad product portfolio results from the fact that CeramTec has already invested in three ULTRASONIC machines from DMG MORI: one ULTRASONIC 20 linear for the complete machining of complex ceramic parts, one ULTRASONIC 60 FD for peripheral grinding of Si3Ni4 and SiC components with highest precision requirements as well as one ULTRASONIC 40 eVo with PH 150-8 for the grinding of hard metal dies.

The properties of technical ceramics today far exceed what is associated with conventional ceramics. They are far from being brittle or fragile. If required, ceramic components replace high-strength steel components in mechanical or automotive engineering. "Ceramic components can even have a springy effect," said Frank Ostertag, responsible for production planning at the headquarters of CeramTec. "Though not well known to the industry, there are numerous application options for which ceramics are a viable alternative. Technical ceramics can potentially have significant advantages, such as their tremendous thermal resistance."

With its expertise in the field of modern high-performance ceramics, CeramTec develops and makes products from scratch - including ceramics production starting with the powder. "We can thus resort to a broad material range and use suitable ceramics for every task," said Biljana Sevdic, also responsible for production planning in Plochingen. Normally, CeramTec first builds a pressing form for the end product; afterwards the part gets sintered. The subsequent grinding ensures that the products meet the high quality requirements.

Extending the Range of Services with ULTRASONIC Technology

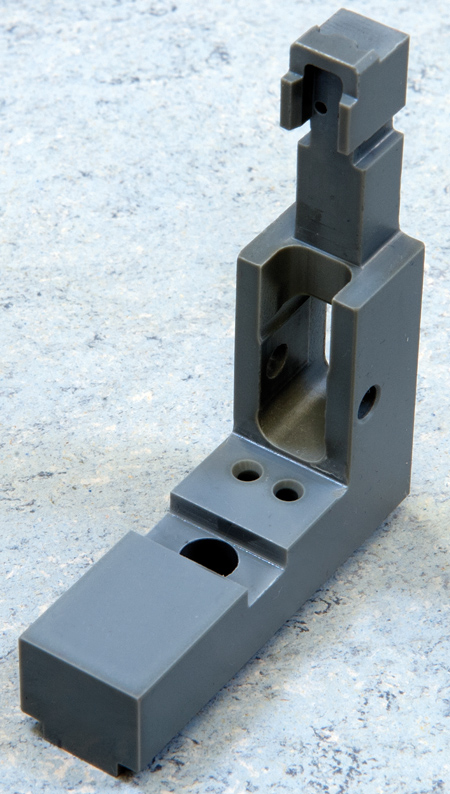

While CeramTec machines numerous workpieces with conventional grinding machines, the company now also has three DMG MORI 5-axis ULTRASONIC machines at its disposal. "The 5-axis simultaneous machining by means of ultrasound has considerably extended our ceramics product portfolio," said Frank Ostertag when describing the increase of the machines available for production. "The ULTRASONIC 20 linear enables the complete machining of our more complex, and in terms of precision, more demanding parts. The ULTRASONIC 60 FD is used among others for peripheral grinding and drilling of Si3Ni4 and SiC components with highest precision requirements. And the ULTRASONIC 40 eVo with PH 150-8, installed at the site in Lauf, Germany, is for direct grinding of hard metal extrusion dies."

Once CeramTec got into complete machining of ceramic components with the ULTRASONIC 20 linear - this includes a number of other smaller components, in addition to dental implants - a conclusion was quickly drawn that the technology was also interesting for larger workpieces. "We have been able to further extend our options with the versatile ULTRASONIC 60 FD," said Ostertag when describing the acquisition. "The turning function, combined with the sturdy machine design and ultrasonic machining enables outstanding precision during peripheral grinding. Equipped with the PH 150|8 pallet handling the ULTRASONIC 40 increases the productivity of CeramTec. While the individual pallets with the hard metal pressing dies are prepared in parallel to production, the machine can optimally run at full capacity."

Sevdic sees a crucial advantage in 5-axis simultaneous grinding compared to working with conventional grinding machines: "We can directly grind complex contours on the ULTRASONIC machines. Conventional grinding machines would be quicker, but a custom made and very costly contoured grinding wheel would be needed each time. This is completely uneconomical, particularly for very small batch sizes or single parts."

"Being able to produce even complex ceramic components economically, CeramTec is able to provide its customers with even better and more economical solutions today. The sales department is thus in a much better position if it wants to offer a suitable component solution," said Ostertag. "This way, we will hopefully be able in the future to use technical ceramics more often, where so far steel or plastic is often used."

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline: 855-DMG-MORI (364-6674)

www.us.dmgmori.com