Grinding Wheel Arbor for Producing Shaped Bone Fragments for Surgical Grafting

April 1, 2016

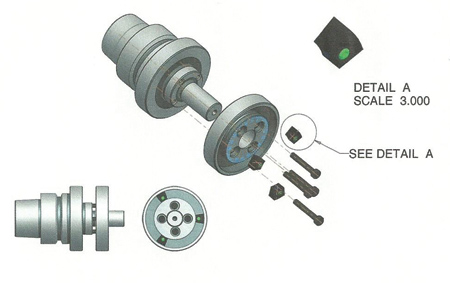

3-D model rendering of Briney HSK50E arbor for grinding shaped bone fragments

Briney Tooling Systems has worked closely with a medical manufacturer to develop a HSK50E balanceable grinding wheel arbor. The arbor required special anti-bacterial/viral chrome plating to comply with the demanding requirements of ISO 13485 for medical OEMs and contract manufacturers. The arbor is being used on a special precision CNC grinding machine that shapes bone fragments for surgical grafting.

Briney has comprehensive in-house CNC turning and grinding capabilities, including in-plant heat treatment where the control of the carburizing and hardening process insures that all tools have .050 minimum case depth to maximize tool life and reduce distortion. Briney was able to design, produce and deliver the arbor to the customer in six weeks.

For more information contact:

Briney Tooling Systems

700 E. Soper Road

Bad Axe, MI 48413-9497

800-752-8035

briney@geminigroup.net

www.brineytooling.com

< back